Are you confused in choosing the right bricks for your construction? With plenty of options, choosing the right brick can be overwhelming. Traditional bricks have been the go-to choice for decades, but we need to sacrifice the time and cost.

This is where cement interlock bricks come into play. It is the modern solution for most construction-related problems and has been widely preferred for its advantages over other bricks. Let’s take a look at cement interlock bricks to understand if they best suit your needs.

Overview of Cement Interlock Bricks

Cement interlock bricks are cement masonry units designed to interlock with each other to create a strong and stable structure without using mortar. This unique feature of the bricks adds numerous advantages in terms of construction time, durability, versatility and cost-saving, which makes it a popular choice for various construction applications.

Features and Benefits

- Offers good structural integrity through proper bonding without the need for mortar.

- It requires less labour and fewer materials, and is faster to construct, reducing the overall construction cost.

- These bricks prevent the structure from weather, water and pest formation, making them last longer.

- These bricks consume fewer natural resources and energy, making them an eco-friendly option than clay bricks.

- These bricks are easy to maintain due to their robust nature and high durability.

- They offer better thermal solution properties than traditional bricks, which helps in saving energy.

Manufacturing Process of Cement Interlock Bricks

Proportioning

High-quality raw materials such as cement, sand, and aggregates are chosen according to the necessary volume proportion.

Mixing

The cement, sand and aggregate are mixed manually or using mechanical mixtures until they attain the consistency needed for moulding.

Molding & Compacting

The freshly mixed concrete is transferred into the mould with interlocking patterns and compacted to remove air pockets in the concrete. This process is carried out under adequate pressure to get the right shape to ensure proper interlocking.

Curing

The moulded and compacted bricks are kept in a controlled environment free from the sun or wind for the next 24 hours. The bricks are then cured under water for 21 days to achieve their maximum strength.

Applications of Cement Interlock Bricks

- It is widely used for creating pavements and walkways due to their ability to withstand high traffic, durability and aesthetic appeal.

- They are used in the construction of driveways due to their resistivity against heavy loads, wear and tear.

- They can be used to build boundary walls, fencing and other outdoor structures due to their weather-resistance properties.

- The cost-effective nature of these bricks makes them suitable for low-cost housing.

- They can be used for landscaping projects such as garden paths, patios, and terraces.

Installation Process of Cement Interlock Bricks

- Ensure that the surface is free from dust, debris, vegetation or any kind of impurities that could affect the construction process. Keep the surface level and compacted to create a flat and even base.

- Install the sub-base layer using crushed stone, gravel, or sand and compact them to allow proper drainage and prevent shifting. The sub-base should be thin, typically 2-4 cm, to create a stable surface.

- Began laying the interlock bricks from one corner towards the other by securely interlocking them in the correct alignment. Use a rubber mallet for proper interlocking and aligning them in a straight and consistent pattern.

- The corner bricks can be cut based on the measurement to fill the gaps. The cutting process needs to be precise and should ensure that it doesn’t misalign with the other bricks.

- Fill the gaps between the bricks using sand to ensure proper interlocking and prevent shifting. The sand should be fine and dry, cover the entire surface, and be compacted to fit and stabilise the surface.

- Excess sand on the surface is removed by sweeping, and a plate compactor is run over the surface to ensure the levelling.

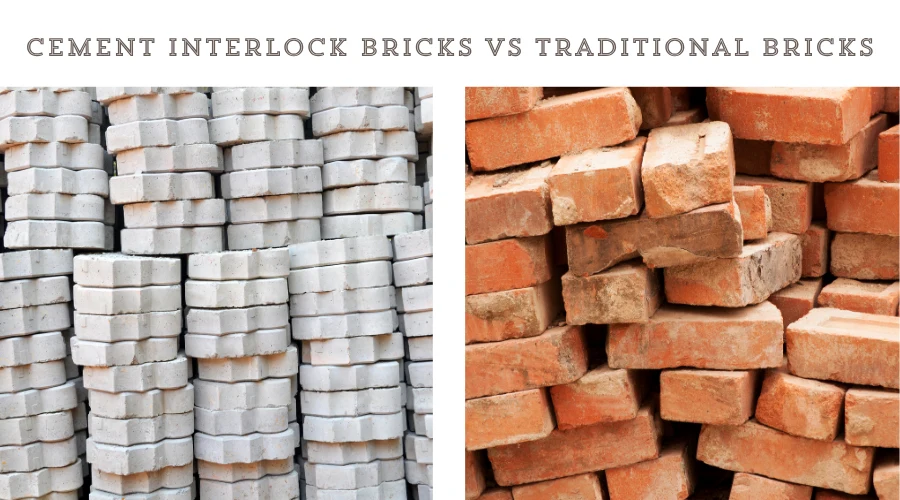

Cement Interlock Bricks vs Traditional Bricks

| Feature | Cement Interlock Bricks | Traditional Bricks |

| Installation | Quick and mortar-free installation. Bricks interlock securely, reducing the need for additional bonding agents. | Mortar is required to bond bricks, leading to a slower installation process. |

| Durability | Highly durable and resistant to weather, wear, and pests.. | Durable but may degrade over time, especially in harsh weather conditions. It can be prone to cracking. |

| Cost | Generally more cost-effective due to reduced labour and fewer materials needed (no mortar required). | Typically high cost due to the need for mortar, labour, and other materials like reinforcement. |

| Maintenance | Low maintenance is required due to their durability and resistance to weathering, water, and pests. | Higher maintenance due to potential mortar erosion, cracks, and damage. |

| Construction Time | Fast installation, as there’s no need for mortar curing time. Building can proceed more quickly. | Slower due to the need for mortar application and curing. |

| Environmental Impact | More eco-friendly as they use less energy in production and fewer resources (no burning process like traditional bricks). | Higher environmental impact because of the energy-intensive burning process and raw materials used. |

| Strength | The interlocking design provides good strengthand even distribution of forces. | Strength is dependent on the quality of mortar and brick quality. |

| Aesthetic Flexibility | Available in a variety of sizes and patterns, offering some design flexibility. | Typically available in standard sizes and shapes, but can be limited in design options. |

| Application | Ideal for pavements, flooring, low-cost housing, boundary walls, and landscaping projects. | Primarily used for walls, foundations, and other structural elements in buildings. |

Conclusion

Cement interlock bricks are a modern solution for traditional brick masonry. The interlocking pattern offers high stability, strength, and faster construction at an affordable cost. Their increased durability with limited mortar usage reduces the overall cost, making it an affordable option. It is used for a wide variety of applications, from pavements to walls, which is a clear advantage over other brick types. We hope this blog has helped you in understanding cement interlock bricks and helped you in deciding the suitability of your construction needs.