The quality of aggregates plays a major role in determining the durability of construction materials like concrete and asphalt. With the different types available, uniformly graded aggregates stand out due to their unique composition and specific applications.

Aggregates are known for their consistent particle size. They bring both benefits and limitations depending on the intended use. Want to understand why they matter and how they are used in construction? You are at the right place! In this blog, we will explore the applications and possible drawbacks of uniformly graded aggregates.

What is Uniformly Graded Aggregate?

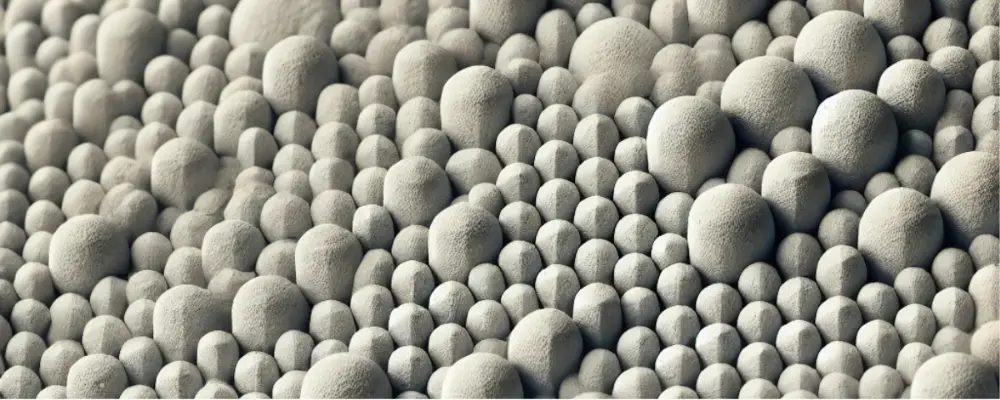

Uniformly graded aggregate refers to a collection of particles predominantly of the same size, with little variation or gradation. This is in contrast to well graded aggregates, which consist of a mix of various particle sizes to fill gaps and achieve maximum density.

If a batch of aggregate contains mostly 10 mm particles, with minimal presence of smaller sizes, it is considered to be uniformly graded. This consistent size distribution leads to specific behaviors in the final product, particularly in terms of compaction and drainage.

Importance of Uniformly Graded Aggregates in Construction

Uniformly graded aggregates have specific applications where their characteristics align with the functional requirements of the project. Here is why they are important:

Drainage Efficiency:

Their uniform particle size ensures excellent permeability. This makes them perfect for projects requiring efficient drainage, like subbase layers and retaining wall backfills.

Controlled Void Spaces:

These aggregates maintain consistent void ratios. This is important in certain applications like filters in wastewater management and road base construction.

Specialised Applications:

Uniform gradation is necessary for niche applications like railroad ballast and decorative concrete, where specific properties are needed.

Properties of Uniformly Graded Aggregates

Particle Size Consistency:

Uniformly graded aggregates have minimal variation in particle size. They create distinct void spaces in a concrete mix.

Low Compaction Ability:

Due to the lack of smaller particles to fill voids, these aggregates don’t compact as tightly as well graded aggregates.

High Permeability:

The open structure facilitates water flow, making them excellent for drainage applications.

Reduced Cohesion:

Uniform grading often results in less interlocking between particles. This can affect stability in load bearing applications.

Applications of Uniformly Graded Aggregates

Uniformly graded aggregates have excellent properties and are used in various applications. Following listed are a few applications of uniformly graded aggregates:

Drainage Systems:

Uniformly graded aggregates are highly used in drainage systems. Their high permeability makes them perfect for sub drains and retaining walls. They can also be used in septic system leach fields.

Asphalt Pavements:

Uniformly graded aggregates are used in specific layers of asphalt pavements where permeability and flexibility are important.

Decorative Concrete:

Decorative concrete uses uniformly graded aggregates to create aesthetically pleasing finishes, especially when concrete is left exposed without any finishing.

Railroad Ballast:

Large sized uniformly graded aggregates are used to stabilize railway tracks. They ensure proper drainage and load distribution.

Backfilling:

In projects requiring controlled drainage and reduced water retention, like bridge abutments and underground utility trenches, uniformly graded aggregates are preferred.

How to Identify Uniformly Graded Aggregates?

The identification of uniformly graded aggregates can be done using the following methods:

Sieve Analysis:

Sieve analysis is a standard test to determine the particle size distribution of aggregates. Uniform grading will show a concentration of particles within a narrow size range.

Visual Inspection:

Aggregates with uniform particle sizes are easy to distinguish visually. This is because they lack the variety seen in well graded mixes.

Void Ratio Measurement:

The high void ratio of uniformly graded aggregates is another characteristic that sets them apart.

Technical Standards:

Refer to grading curves and specifications provided by ASTM and IS codes. These standards clearly define the criteria for uniform grading.

Advantages and Disadvantages of Uniformly Graded Aggregates

Uniformly graded aggregates are both a blend of advantages and disadvantages.

Advantages of uniformly graded aggregates.

High Permeability:

The uniform structure of these aggregates allows water to pass through freely, making them highly effective for drainage systems. This reduces risks like waterlogging and helps maintain structural integrity in moisture sensitive areas.

Ease of Placement:

Uniformly graded aggregates are simple to handle and place due to their consistent particle size. It saves time and effort in construction projects.

Reduced Settlement:

In applications like railroad ballast, their uniformity ensures stability and minimises settlement. This will enhance long term reliability.

Specialised Uses:

These aggregates excel in specific applications like decorative concrete and filter layers. In applications like drainage systems, their unique properties are a must-have.

Disadvantages:

Low Strength:

The lack of smaller particles to fill voids reduces strength and stability, making them unsuitable for high load applications.

Poor Compaction:

Uniformly graded aggregates do not compact tightly. This can lead to uneven settlement in some cases.

Limited Versatility:

They are not suitable for general purpose concrete and asphalt mixes. This is because well graded aggregates are preferred for strength and durability.

Cost Considerations:

For certain projects, the specific processing required to achieve uniform grading can increase costs.

Conclusion

Uniformly graded aggregates play a major role in construction, particularly in applications where permeability and drainage are key requirements. Their consistent particle size offers ease of placement and stability in specific scenarios like railroad ballast and drainage systems. Understanding their properties and selecting the right aggregate for a project can ensure optimal performance and long term durability.

FAQs

No. Uniformly graded aggregates are perfectly suited for specialised applications like drainage systems and railroad ballast. For general purpose concrete and asphalt, well graded aggregates are typically preferred for their superior strength and compaction properties

Standards like ASTM C136 and IS 383 specify grading requirements for aggregates. These documents include guidelines for sieve analysis and particle size distribution to classify aggregates as well graded and uniformly graded.

Uniformly graded aggregates generally do not enhance the durability of concrete due to their reduced compaction and interlocking ability. They improve permeability, making them perfect for drainage oriented applications.