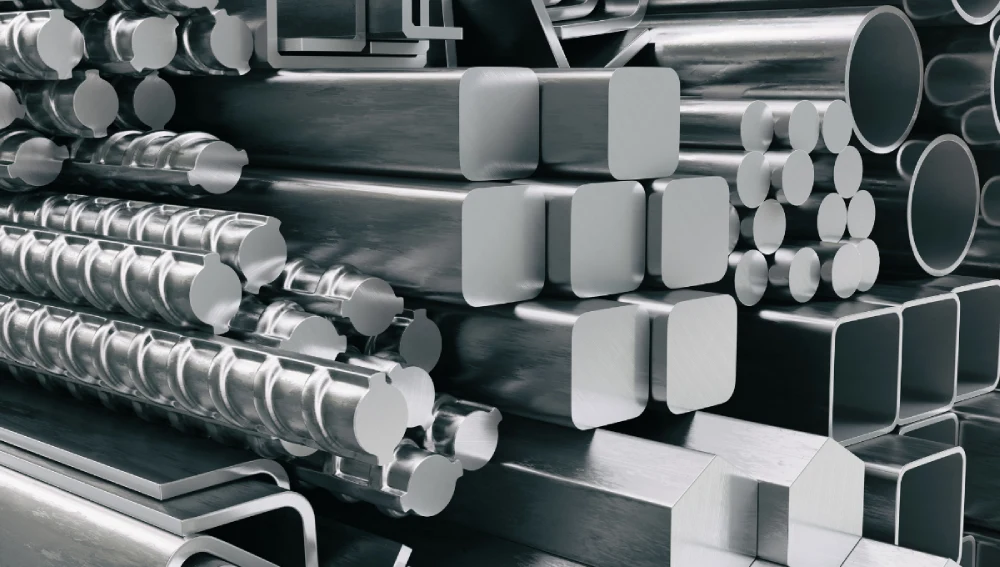

Stainless steel fabrication is a commonly used methodology in the modern construction industry. Its process includes cutting, shaping or bending, designing, assembling, and welding for conversion into various forms to be used for commercial, domestic, and industrial purposes. Stainless steel is known for its 100% recycling nature. The main composition of stainless steel is nickel, iron, and chromium. Corrosion resistance and smooth surfaces are its key features. Read on to learn about how this material is being used by the construction industry through fabrication.

What is Stainless Steel Fabrication?

Stainless steel fabrication is defined as converting stainless steel into a particular shape or form through the application of different processes and methodologies. The steps involved in forming stainless steel are highly technical. It contains a minimum of 10.5% chromium, which makes it corrosion-resistant.

Stainless steel was invented back in the 20th century. by Harry Brearley, a British metallurgist, He found that when chromium is added to steel, it makes it resistant to rusting. A revolution was created in the metal industry by his discovery. Various grades of stainless steel were then developed with different properties.

Process Breakdown

Fabrication involves various processes for altering stainless steel in order to transform it into usable shapes, forms, and products. Some of these processes are:

Cutting

Cutting large elements of stainless steel into usable sizes is one of the crucial steps of the fabrication process.

Some cutting techniques used are:

- Metal punching

It is also known as sheet metal punching. It is a process in which excess shear pressure is applied to cut the stainless steel sheets at specific locations.

- Shearing

Shearing is a process in which large rolls of stainless steel are cut into smaller sheets. Conventional press/ guillotines used for shearing other such metals can be used for stainless steel as well.

- Laser cutting

A laser beam can be used to melt the stainless steel in specific sections where it needs to be cut. This process is a noncontact cutting process. A significant amount of energy in the form of light is transferred to the sheet metal. Heat is created, and it vaporizes parts of the steel in order to break it into pieces.

- Other types of cutting:

- Abrasive Cut-Off Saw.

- Plasma cutting,

- Flame cutting,

- Circular saw cutting

- Oxy-Acetylene Saw.

- Plasma Cutting

- Water Jet Cutting

- Circular Saw.

- Angle Grinder

- Jigsaw.

Forming

Forming refers to subjecting stainless steel to different types of deformation in order to obtain the desired physical properties of shape and size. This includes several processes, like:

- Bending: Flat stainless steel sheets and bars can be bent using bending machines or press brakes. Tubular elements are more difficult to bend and require rotary bending machines or hydraulic presses.

- Rolling: The stainless steel sheet is passed through a series of rollers to form a cylindrical shape. This process is useful for creating lightweight structural parts.

Stamping and punching:

A punch gives shape to the stainless steel sheet through a complex process that involves mechanical methods. This process is similar to carving and can be used to add patterns to the stainless steel. It is highly used in industries such as automotive aerospace electronics where precision is required. This process is generally used for bulk quantities and high volumes.

Welding

Welding is the process of joining two metals The material parts are melted by heating and joined upon cooling. It is an important process that helps build the desired shapes.

Arc welding

It is used in electric arcs where two pieces of metal are joined together by melting. Arc welding types are:

- Carbon arc welding

- Submerged arc welding

- Shielded metal arc welding

MIG or MAG welding

It is also known as metal inert gas welding. A wire electrode and shielding gas can join two pieces of metal, including stainless steel.

Spot welding:

Two pieces of metal are joined together by applying pressure and heat in a small spot. This process is called spot welding. It is an efficient technique for joining without any additional material.

Machining

Stainless steel sheets are further processed using various types of machines. This is called machining.

Milling

It involves the removal of materials from the steel sheet using a rotary cutter. The main purpose is to create complex holes, shapes, etc.

Turning:

It is a process that uses a lathe machine to rotate the metal. A cutting tool is used to remove metal along the diameter. It works in a linear motion and results in creating a cylindrical shape. The cutting tool can be set at various angles according to the desired form.

Drilling:

Drilling stainless steel requires the usage of specialised drill bits and machines. This process does not require expertise or the use of factory equipment, however, adequate protective gear must be used for safety.

Surface finishing

Grinding

Grinding creates a smooth surface on the stainless steel by removing excess or unwanted material. This gives a mirror-like finish. It is done by using a grinding wheel and is called surface grinding. Abrasive belts can also be used as a cutting tool for grinding.

Polishing:

Polishing is used to give a glossy finish to the stainless steel surface. This makes it highly reflective and is a finer abrasive process than grinding. It is a traditional method that improves the surface quality and prevents rusting.

Passivation

The removal of impurities from stainless steel is called passivation. It is a chemical treatment that improves durability and prevents corrosion. In this process, chemical acid solutions are applied. For example, nitric acid or citric acid removes free ions from its surface.

Assembly

Joining components

The final product is obtained by joining the individual fabricated components. This can be done by welding, bolting, riveting, etc.

Fitting and alignment

Correct alignment and tolerance are required to obtain the final assembly. The precise fit of all parts ensures the quality of the product.

Conclusion

Stainless steel has unparalleled benefits and plays a vital role in various construction industries. These benefits include environmental sustainability, longevity, and low maintenance. Fabrication of stainless steel allows its physical modification in order to convert it into usable forms and products. This enables versatility in its usage and makes it an important aspect of the construction industry.