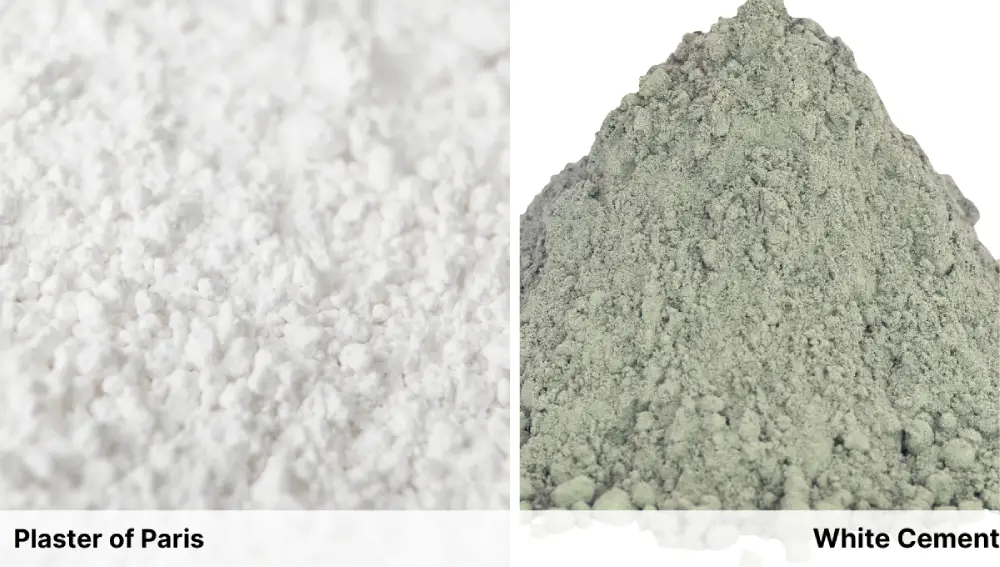

Regarding interior and exterior finishing in construction, both Plaster of Paris and white cement are considered two prominent materials. Each has its unique properties, applications, and advantages. Understanding the differences between Plaster of Paris and white cement can help select the right material for specific needs.

This blog offers a detailed comparison between Plaster of Paris (POP) and white cement and their properties.

Are Plaster of Paris and White Cement Identical?

Although both POP and white cement are used in construction works, they have differences in key properties. Plaster of Paris is commonly used because of its fast setting time and is commonly used for artistic works. Its low strength and high water absorption capacity make it less durable when compared to white cement.

White cement is made of cement-based materials and it takes a long time to set. However, it offers a hard and durable finish. It is commonly used in construction for filling, binds, and leveling surfaces because of its durability and strength.

Composition

Plaster of Paris

Plaster of Paris is composed of gypsum and the main element is calcium sulfateIt is obtained by heating calcium sulfate hemihydrate to 300 degrees Fahrenheit in the presence of water.

The chemical reaction is,

CaSO4 (2H2O) + heat (150 degree Celsius) → CaSO4 .1/4H2O + 3/4H2O

If the gypsum is heated at a 393K temperature, the water molecule evaporates, and plaster of Paris is made. Meanwhile, if Plaster of Paris is mixed with water, it converts into gypsum.

White Cement

White cement is a Portland cement type and as the name suggests, it is distinctly white in colour. Calcium carbonate and clay are the main materials in white cement, but it also contains small amounts of manganese oxide and iron oxide. The production of white cement involves a controlled burning process at an approximate temperature of around 2642 degrees Fahrenheit. Then followed by cooling and grinding, white cement is obtained.

Difference between Plaster of Paris and White Cement

| Aspect | Plaster of Paris (POP) | White Cement |

| Composition | Made from gypsum, which is heated to form a fine powder. | Made from limestone and clay, containing more lime and iron oxide. |

| Setting Time | Sets quickly, around 20-30 minutes. | Initial setting time is 45 minutes, and the final setting time is 8-10 hours. |

| Strength | Lower compressive strength (5-15 MPa). | Higher compressive strength (20-50 MPa). |

| Colour | White or off-white in appearance. | Pure white, with a whiteness of around 80-84%. |

| Density | Lower density (700-900 kg/m³). | Higher density (1400-1500 kg/m³). |

| Durability | Less durable and prone to cracking over time. | Highly durable and resistant to moisture. |

| Moisture Resistance | Poor; not suitable for damp or wet areas. | Excellent; suitable for both interior and exterior applications. |

| Uses | Used for ceilings, moldings, and decorative work. | Used for wall putty, waterproofing, and tile fixing. |

| Finish | Generally more affordable. | More expensive than POP. |

| Application | Easy to apply, ideal for quick projects. | Requires more effort and time for application. |

Applications

Plaster of Paris

- Architecture and Decorations: POP is used in creating intricate decorative items such as false ceilings, mouldings, and cornices. This helps in producing artistic and creative finishes in buildings.

- Art: POP is used for crafting detailed sculptures. It gives a smooth and workable medium that can give finishes similar to wood or stone.

- Medicine: In the medical field POP can be used for making casts and molds. It forms an orthopaedic cast to mobilise broken bones, thus providing a sturdy and supportive structure.

- Fireproofing: POP is used in various fire protection and fireproofing products. It helps to reduce the fire spread in buildings.

- 3D Printing: In recent years POP has been used in 3D printing as it helps in creating detailed and precise models.

White cement

- Building Projects:When white cement is combined with colour pigments, it gives striking visual effects without any compromise to structural integrity. It is also used in ornamental pillars and false ceilings.

- Custom floors: Combining white cement with marble powders, marble chips, and colour pigments gives limitless possibilities for custom designed floors.

- Filling gaps in tiles: White cement can be used to fill the gaps in ceramic, vitrified tiles, and marble floors. Adding this makes the floor appear like a monolithic slab and the most difficult task is to remove the white cement in the tiles

- Sealant: White cement can be used as a sealant for gaps that occur when installing bathroom fixtures and other plumbing fittings.

Advantages and Disadvantages

Advantages Of Plaster of Paris

Plaster of Paris is durable and lightweight. It has low thermal conductivity and excellent fire resistance, acting as a heat insulator. It adheres well to fibrous materials and provides a smooth, firm surface for painting, preventing alkali attacks and chemical reactions. It offers a decorative interior finish with the ability to be molded into various shapes.

Disadvantages of Plaster of Paris

Plaster of Paris is more expensive than cement or cement lime plaster. It requires a professional application and is not suitable for exterior finishes due to its slight solubility in water and inability to withstand excess heat, which can lead to an untidy appearance.

Advantages of White Cement

White cement provides exceptional durability and strength. It has a pure white colour that gives aesthetic appeal and design flexibility with a range of colour options. The low alkali content helps in reducing chemical reactions and improves lifespan. Additionally, the reflective properties of white cement help in keeping outdoor surfaces cool.

Disadvantages of White Cement

White cement is more expensive than grey cement due to its production methodology. Maintenance has to be done carefully as it tends to be discoloured or stained easily. White cement must be handled with proper professionals and if the curing process is improper, then it affects the colour and durability. Additionally, the reflective properties of white cement may cause glare.

Plaster of Paris and white cement are important in construction, and each has its specific applications. Plaster of Paris can be used for quick setting, lightweight, and decorative uses, while white cement provides strength, durability, and aesthetic appeal.

It is important to understand their properties before applying them practically to ensure the desired outcome from your work.

FAQs

Plaster of Paris is more suitable for intricate artistic work.

Plaster of Paris is known for its smooth finish.

White cement’s reflective properties help keep surfaces cool in hot climates.

A key advantage of Plaster of Paris is its quick setting time.

White cement has a higher compressive strength.