The fundamental construction element is concrete, a versatile material that shapes the built environment around us. Knowing concrete components is crucial when you are building your dream home. Cement is an essential component of the concrete mix, and getting the right amount is essential to building a sturdy and long-lasting structure. This blog explores how many bags of cement are required for one cubic meter of construction and the factors affecting the amount of cement required. But before we start to learn in detail, let’s understand what cement is and its importance.

What is Cement & Its Importance?

Cement is used as a binder in construction, binding other materials together through setting, hardening, and adhering to them. It’s one of the essential ingredients of both regular cement concrete and reinforced cement concrete-RCC.

You make concrete by combining cement, sand, aggregate, and water, which are key components for slab casting, RCC structures, bridges, roads, dams, and other pre-cast concrete elements. You can also make a cement mortar by mixing sand and gravel, which is mostly used for plastering and brickwork; brickwork means the laying of brick.

You can use different types of cement, such as Ordinary Portland Cement (OPC), Portland Pozzolana Cement (PPC), Rapid Hardening Cement, Extra Rapid Hardening Cement, Quick Setting Cement, Low Heat Cement, Sulphate Resisting Cement and more, according to your requirements.

How Many Bags of Cement Required for One Cubic Meter

To calculate the cement bags required for one cubic meter, you have to consider the concrete mix design ratio for your construction. The concrete mix design ratio is the ratio of water, cement, sand, and aggregate in a concrete mix. The strength, workability, and durability of your building are all directly impacted by this ratio. Hence, selecting the proper proportion for concrete mixing is essential to guarantee that your building will be strong and durable.

Calculation of how many bags of cement to make 1m3 of concrete 1:2:4

To calculate the cement requirement per cubic meter construction, you must find out the total volume of cement and the volume of 1 bag of cement.

So, for the cement volume calculation, let’s assume your concrete design mix ratio is 1:2:4, which means that 1 part is cement, 2 parts are sand, and 4 parts are aggregates. Along with the precise ratio, also consider the loss of cement as cement’s particles are too small. Hence, there is a high chance of losing it. So, assume a 2% of cement loss.

If you assume that the output of the mix is 67%, then the required dry mix to achieve 1 cubic meter output is-

1/Total output of the mix

=1/0.67

=1.49 round figure 1.50 cubic meter dry mix.

Now, you also need to add cement wastage to it. So, wastage is 2%,

So, total dry mix + 2% wastage

=1.50+0.02

= 1.52 cubic meters.

Now, you have to calculate the total volume of cement,

= Volume of cement = Total material × (cement/cement+sand+aggregate)

= 1.52 × (1/1+2+4)

= 0.2171 cum

Now, the standard weight of 1 bag of cement is 50 kg, and the density of cement is 1440 kg/cubic meter.

Therefore, the volume of 1 bag of cement,

= 50/1440

=0.0347 cum.

Hence, no. of cement bags required for 1 cubic meter of construction is,

= Total volume of cement/ volume of 1 bag of cement

= 0.2171/0.0347

= 6.25 bags.

So, the number of bags of cement required per cubic meter of 1:2:4 concrete will be approximately 6.25 cement bags.

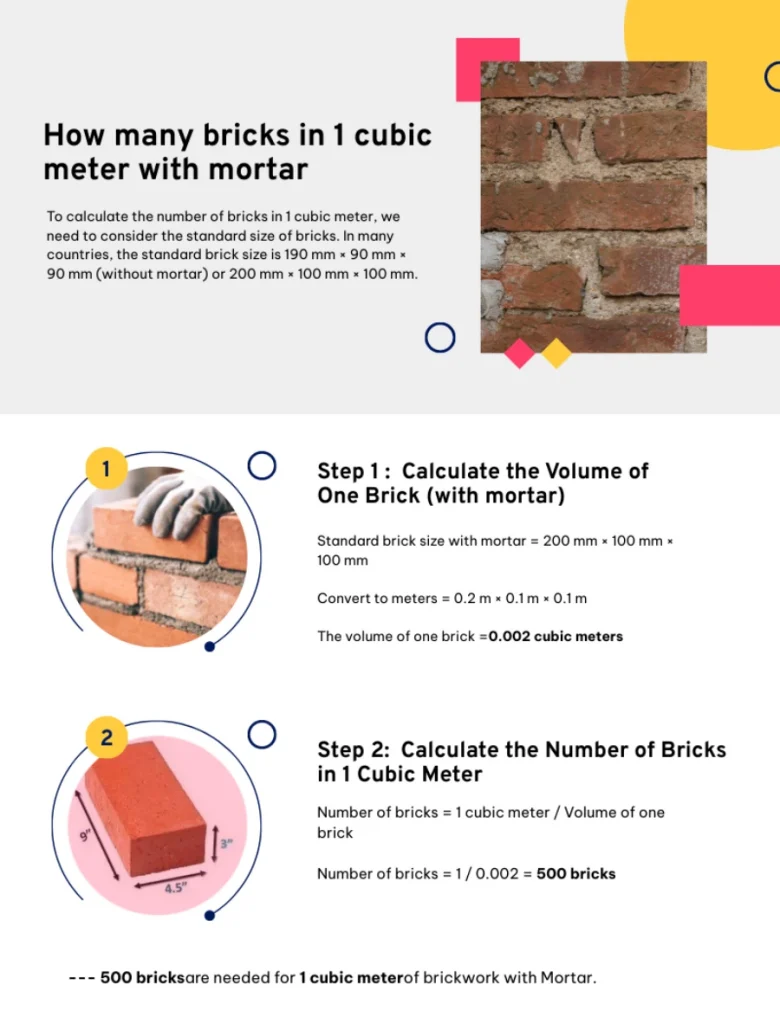

How many bricks in 1 cubic meter with mortar

To calculate the number of bricks in 1 cubic meter, we need to consider the standard size of bricks. In many countries, the standard brick size is 190 mm × 90 mm × 90 mm (without mortar) or 200 mm × 100 mm × 100 mm.

Step 1: Calculate the Volume of One Brick (with mortar)

Standard brick size with mortar = 200 mm × 100 mm × 100 mm

Convert to meters = 0.2 m × 0.1 m × 0.1 m

The volume of one brick = 0.002 cubic meters

Step 2: Calculate the Number of Bricks in 1 Cubic Meter

Number of bricks = 1 cubic meter / Volume of one brick

Number of bricks = 1 / 0.002 = 500 bricks

500 bricks are needed for 1 cubic meter of brickwork with Mortar.

The calculation for cement required for 1 cubic meter of brickwork 1:4

To calculate the cement required for 1 cubic meter of brickwork with a mix ratio of 1:4 (1 part cement and 4 parts sand), we’ll follow a similar approach:

Step 1: Understand the Mix Ratio

Mix ratio: 1:4 (1 part cement, 4 parts sand)

Total parts: 1 (cement) + 4 (sand) = 5 parts

Step 2: Calculate the Dry Volume of the Mortar

The volume of dry mortar is approximately 30% more than the wet volume of mortar. So for 1 cubic meter of brickwork, the dry volume of mortar required is:

- Dry volume of mortar: 1 cubic meter * 1.30 = 1.30 cubic meters

Step 3: Calculate the Cement Volume

The cement volume is calculated as:

Cement volume = (Dry volume×Cement part)/Total parts

Cement volume = (1.30×1)/5=0.26 cubic meters

Step 4: Consider Cement Wastage

Assume 2% wastage for cement, so the effective volume of cement needed:

Total cement volume = 0.26 cubic meters×1.02 = 0.2652 cubic meters.

Step 5: Calculate the Number of Cement Bags

The volume of one bag of cement (50 kg) is calculated as:

Volume of 1 bag of cement (in Cubic Meters) = 50 kg/1440 kg = 0.0347 cubic meters

Now, calculate the number of cement bags required:

Number of cement bags (in cubic meters) =0.2652/0.0347 = 7.64 cubic meters/bag.

So, the cement bags required for 1 cubic meter of brickwork 1:4 is 7.64 Bags.

The following factors influence the requirement for cement.

1. Concrete Mix Design Ratio:

The requirement for cement varies depending on the concrete mix design ratio means 1:2:3 or 1:1.5:3 or 1:2:4, etc. If you want stronger concrete, it typically requires a higher cement content.

2. Water-Cement Ratio:

The workability and strength of the concrete depend on maintaining a proper water-cement ratio. To maintain workability, you have to increase the water-cement ratio, which influences the cement requirement.

3. Aggregate Size and Type:

The size and type of aggregates affect the interparticle space, affecting the total volume of the concrete and, ultimately, the requirements of the cement.

4. Concrete Strength:

The amount of cement used in a concrete depends on its intended strength. You need more cement for high-strength concrete mixes than lower-strength ones.

Importance of the Material Estimation

For the best construction quality and precise budget planning, it is imperative to know how to estimate the construction cost and quantity of material, as the material cost is 60% of the total construction cost. Your build-up area indicates the amount of materials needed for construction, and the costs may differ depending on the contractors and their location. For instance, compared to the internal material supply chain of a reputed construction company like Brick&Bolt, buying cement from regional suppliers through regional contractors might be more expensive.

Conclusion

On a final note, the amount of bags of cement required for one cubic meter of concrete depends on several factors, including the mix ratio, the desired strength, and the properties of the aggregate. It is important to ensure that the final concrete meets structural specifications to achieve an effective balance between strength and cost. Always adhere to industry norms and regulations to get the best possible outcomes for your dream construction project.