A home is an oasis where you may unwind and experience a sense of serenity. As long as you are emotionally connected with it, it doesn’t matter whether your house is a huge mansion or a small cozy cottage. You can call that space your home, which is surrounded by walls, roofs, doors, windows and most importantly, your emotions and desires. The wall is the most crucial fundamental house component; it can be either a structural or non-structural component. Therefore, selecting the right types of bricks for your home construction is crucial, especially because there are so many types of bricks available on the market, including sun-dried bricks, burnt clay bricks, concrete bricks, fly ash bricks and so on.

Hence, to resolve your confusion about how many types of bricks are available in the market and which types of bricks are the most suitable for your home construction? Brick & Bolt brings a detailed guide on the types of bricks, including what brick is and the qualities of good bricks.

So, let’s start with what brick is.

What are Bricks?

Bricks are rectangular and small blocks which are used in your home construction process, usually in the construction of walls, the most crucial component of the house. They are usually composed of clay, sand, lime, or concrete. Bricks are often used to construct pavements, walls, and other architectural elements. Bricks may be made in a wide range of shapes and types based on the materials they are made of and the intended usage. They are still a common construction material because of their durability, strength, and fire resistance.

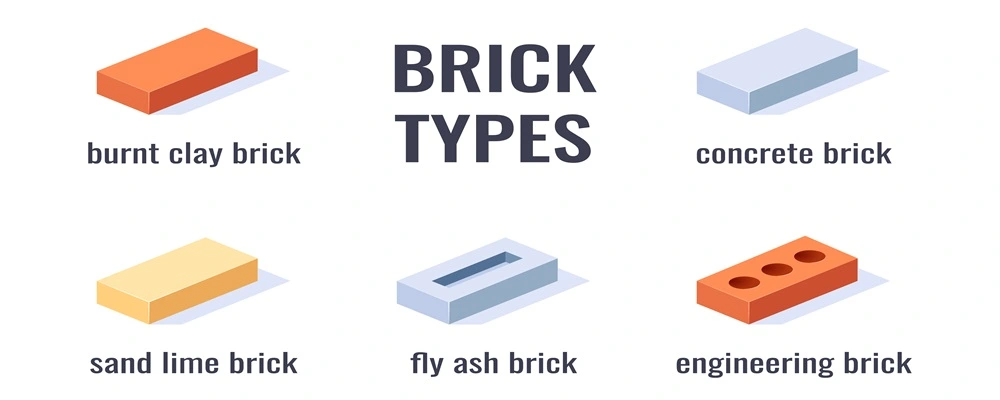

Different Types of Bricks Used in Construction

- Sun-dried bricks

- Burnt clay bricks

- Concrete Bricks

- Fly ash bricks

- Calcium Silicate Bricks

- Engineering Bricks

- Eco Bricks

- Hollow Bricks

- Fire Bricks

Let’s explore all the types of bricks available in civil engineering.

1. Sun-dried Bricks

Sun-dried bricks are produced by moulding wet clay combined with fibers like straw and then letting them dry in the sun. Although these types of bricks are less expensive to make and are often used for temporary buildings, they are not as long-lasting and durable as burnt clay bricks.

2. Burnt Clay Bricks

Clay burnt bricks are produced by moulding wet clay, which is then fired in a kiln at a high temperature. They are durable and strong, hence, widely used in building construction, particularly in regions with a lot of clay. Clay burnt bricks are available in various sizes, shapes, and colours. These types of bricks are divided into four different categories:

1) First Class Bricks

The first-class bricks are of the highest quality bricks, as they undergo table moulding before being fired in a kiln. Moreover, they are stronger and more resilient than all the other types of bricks used in construction. They are homogeneous in terms of size, shape, and colour. They don’t have any flaws and have sharp edges. When hit, the first-class bricks make a distinct ringing noise. Generally, load-bearing buildings and exposed walls are constructed using first-class brick.

2) Second Class Bricks

The second-class bricks resemble the first-class bricks, yet they might contain a few little flaws like strange colours, sizes, or shapes. They lack a flawless form and texture since they are ground-molded. The second-class bricks are the second-strongest type of bricks in civil engineering since they are also burned in kilns. They can not be utilized for exposed walls, although they are still appropriate for load-bearing walls.

3) Third Class Bricks

Instead of burning in kilns, the third-class bricks are ground-molded and burned in clamps. These types of bricks contain noticeable cracks, distortions, and other flaws, and they are quite asymmetrical in size, shape, and colour. They belong exclusively to temporary buildings as they are similar to unburned bricks. The third-class bricks are often used for non-structural uses like garden walls and landscaping, but they are not appropriate for load-bearing constructions.

4) Fourth Class Bricks

Fourth-class bricks are of poor quality and either over- or under-burnt. Due to the possibility of cracks, distortions, and other flaws, these types of bricks cannot be used in any kind of building. Before being utilized in construction, they are crushed and combined with concrete.

3. Concrete Bricks

Sand, cement, water, and coarse aggregates are used to make concrete bricks. They may be produced on the building site and customized to fit various sizes. These types of bricks are durable, strong and resistant to weathering and fire. Concrete bricks are often used as paving stones and in load-bearing constructions.

4. Fly Ash Bricks

As a raw material, fly ash bricks consist of a combination of cement, water, and fly ash- a waste material from coal-fired power plants. To produce fly ash bricks, first thoroughly mix all the ingredients, then compress the mixture into moulds. They are often utilized for load-bearing constructions since they are an affordable and environmentally friendly alternative to conventional clay bricks. These types of bricks are more resilient to freezing and thawing effects and excellent for insulation since they are robust yet lightweight and don’t absorb as much water.

5. Calcium Silicate Bricks

Calcium silicate bricks are also known as sand lime bricks as they are made of sand and lime. In the building industry, these bricks are used for various tasks, and they are one of the main types of bricks used in India. They are strong, long-lasting, and fire-resistant. They may be used in high-rise buildings or other places where thermal insulation is crucial since they are lightweight and have strong insulation qualities. Sand-lime bricks or calcium-silicate bricks are also used in architectural decorative works and other artistic works in construction.

6. Engineering Bricks

Engineering bricks are specifically designed for structural applications. The best clay is used to make them, and it is fired at very high temperatures to make them dense, strong, and resistant to chemicals and water. These types of bricks are frequently used in situations where water resistance is necessary or when significant loads are expected to be imposed.

7. Eco Bricks

Paper, plastic bottles, and other waste materials are recycled to create eco-bricks. Because they are sustainable, these types of bricks are becoming increasingly popular as an environmentally friendly substitute for conventional bricks. This environment-friendly building material is often used for non-structural elements, including garden walls, landscaping, and accent pieces.

8. Hollow Bricks

As the name implies, hollow bricks are also known as cellular or cavity bricks. They are hollow within and weigh around one-third less than ordinary bricks. Because they can be placed much faster than regular bricks, these types of bricks are often employed for speedy construction. Partitions are also made using these bricks during building construction process.

9. Fire Bricks

Fire bricks are also referred to as refractory bricks. These types of bricks are produced through an especially designed earthing procedure. Because of their fire-resistance qualities, they can tolerate very high temperatures after burning without sacrificing strength, shape, and size. Fire bricks are often used for the lining of furnaces and chimneys, which often have very high-temperature rates.

Characteristics of Good Quality Bricks

If you are not sure about how to choose the good quality bricks. Then, you must consider the following characteristics of good-quality bricks.

- The brick should be standard in size and consistent.

- The brick must be rectangular in shape, along with straight and crisp edges.

- A good quality brick should have a consistent colour, which might be either cherry or deep red.

- The surface of the bricks must be rough because excessively smooth bricks cause mortar to slide.

- Bricks need to have a decent enough hardness. When nails are used to scratch a brick, the surface should not be left with any marks.

- When thrown flat from a height of around 1 or 1.2 meters onto firm ground, the brick shouldn’t shatter into fragments.

- It should be free from cracks, holes, lumps, kankars or any other debris.

- Bricks must have a compressive strength of at least 3.5 N/mm2.

- The brick should make a metallic ringing sound when hit with a hammer or another brick.

To sum up, knowing the different types of bricks used in construction is important for picking the right building material for your project. From standard clay bricks to eco-friendly fly ash bricks, each type has its own advantages when it comes to strength, longevity, and insulation. Also, bricks come in a lot of different sizes and shapes, which gives architects a lot of creative freedom when designing buildings. No matter if you are making a commercial or residential structure, choosing the right type of brick can help you get a building that lasts, works well, and meets your needs and expectations.