Just imagine an innovative material in your home that silently works for your comfort, such as absorbing heat when it’s too hot and releasing it when it’s cold. That’s the magic of Phase-Change Materials (PCMs). These materials are designed to keep and liberate heat as they change from solid state to liquid state. By using the natural power of latent heat, PCMs help keep indoor temperatures steady, reducing energy use and making homes more comfortable and energy-efficient. From walls and roofs to floors and ceilings, PCMs are shaping the future of sustainable home construction—one smart layer at a time.

Read this Brick & Bolt blog to understand more about the applications of PCM in house construction.

What Are Phase Change Materials (PCMs)?

PCM is the short form of phase change material; as the name indicates, these materials change their phase from one physical state to another (commonly from solid state to liquid state and vice versa) by absorbing and releasing thermal energy storage. During this transition of states, energy will be released in the form of heat or cooling, enabling the material to keep a specific temperature range. If PCMs melt, they absorb heat from their environs, and contrarily, as they solidify, they release latent heat.

In PCMs, energy will be stored or released by physical state changes or by a change in the internal structure—thus, PCMs are often referred to as latent heat storage (LHS) materials.

Classification of Phase Change Materials

Based on the materials used for manufacturing, phase change materials are classified into the following three types:

1. Organic Phase Change Materials

These PCMs are commonly made of hydrocarbon-based substances. They are again subdivided into paraffin compounds or fatty acids.

- Paraffin: They are most often used in cooling systems as they can retain a lot of heat. This makes it best for energy storage.

- Fatty acids: These PCMs are an eco-friendly substitute as they usually degrade naturally and can be rebuilt.

These PCMs can be recycled with other materials and are chemically stable. They offer high latent heat capacity. However, they offer flammability with low thermal conductivity in a solid state. These materials are more expensive than other options.

2. Inorganic Phase Change Materials

These PCMs are made of inorganic substances like salt hydrates or metals. They are considerably effective in energy storage and have better thermal conductivity than organic PCMs. These PCMs are available at low cost and are non-flammable. Although they exhibit low volume change, these materials tend to corrode. It offers super cooling but has chemical instability

3. Eutectic PCMs

They are prepared with a combination of two or more organic or inorganic PCMs. Accordingly, they are classified as

- Organic-organic PCM

- Organic-Inorganic PCM

- Inorganic-inorganic PCM

Eutectic phase change materials offer high volumetric thermal storage with high melting temperatures. However, they have a strong odour and are costly, with low total latent heat capacity.

List of PMC Materials Along with Their Application

According to the ‘The American Council for an Energy-Efficient Economy- ACEEE’, despite years of research, the practical implementation of Phase Change Materials (PCMs) in building construction still shows certain uncertainties. Although PCMs offer promising energy efficiency benefits, the construction industry continues to explore various integration methods to determine the most effective and feasible approach. The following are phase-changing materials and their applications in house construction.

| Phase-Changing Materials | Application |

| Micro-encapsulated Paraffin Wax | Wallboard Ceiling |

| Tile Floor Panel | |

| Interior Wall Construction | |

| Bio-based (Organic) Materials | Interior Wall Construction |

| Attic/Drop Ceiling Plenum Floor | |

| Eutectic Salt Mixtures | Interior Wall Construction |

| Attic/Drop Ceiling Plenum Floor |

Key Properties of Phase Change Materials

The key properties of PCMs are as follows:

Thermal Properties of PMC

- Low Thermal Conductivity: PCMs generally have low thermal conductivity (typically 0.2–0.4 W/m·K for organic PCMs like paraffin wax). Nano-enhanced PCMs (NEPCMs) incorporating additives such as graphene or metallic nanoparticles can improve this to 1.0–8 W/m·K, depending on the nanoparticle type and concentration.

- High Latent Heat: PCMs store significant energy during phase transitions, with latent heat values ranging from 150–250 kJ/kg for organic PCMs and up to 350 kJ/kg for inorganic hydrated salts. However, the inclusion of nanoparticles may reduce latent heat by 2–15% due to the displacement of the base PCM.

- Melting Point: The melting point varies based on the material composition. For human comfort applications, melting points are often between 20°C and 30°C.

Physical Properties

- A favourable phase equilibrium is essential for PCMs to ensure stable and predictable phase transitions. The melting points of PCMs typically range between 20°C and 60°C, a characteristic that can be tailored based on the specific application, such as maintaining comfortable indoor temperatures in buildings or managing heat in electronic devices.

- PCMs exhibit a high density, typically ranging from approximately 800 to 1000 kg/m³ for Polyethylene Glycol (PEG)-based materials, which allows for compact energy storage systems.

- Their specific heat capacity values generally fall between 2 and 4 J/g·K, enabling efficient absorption and release of heat.

- PCMs undergo only small volume changes during phase transitions, typically less than 10%, which is important for minimizing structural stress on the surrounding materials. This dimensional stability ensures that the integration of PCMs into building materials or other applications does not compromise the integrity of the structures.

- A low vapour pressure, generally less than 1 kPa at operating temperatures, is another critical property of PCMs, ensuring safe containment and long-term stability by preventing material loss through evaporation.

Benefits of Using PCMs in House Construction

The following are the major benefits you can achieve by using PCMs in your house construction:

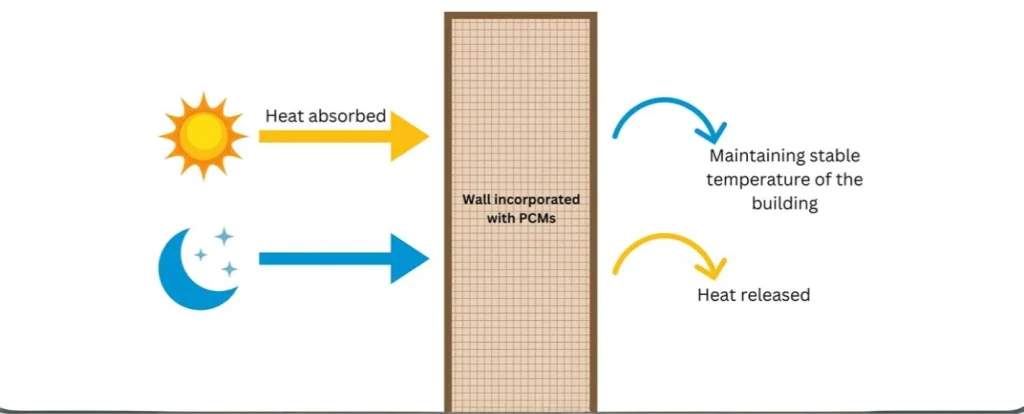

Energy Efficiency: By integrating PCMs in building materials, you can considerably improve energy efficiency in house construction by reducing heating and cooling demands. By absorbing heat during warmer periods and releasing it during cooler periods, PCMs can reduce the need for active HVAC systems with considerable energy savings.

Thermal Comfort: PCMs help to create thermal comfort within the house setting. It reduces temperature modulations by absorbing heat when temperatures rise and releasing it when they drop. By incorporating PCM, the building envelope offers enhanced thermal inertia, which helps to control indoor temperatures and reduce the reliance on mechanical cooling systems.

Sustainability

When you use PCMs in house construction, you can directly reduce the carbon emission connected with HVAC systems. Thus, you can reduce the dependence on fossil-fuel-based heating and cooling. PCMs are the sustainable alternative to combat climate change. According to ‘Jebaei et al. (2024)’, (Published in Energy and Building, Volume 315), Optimal PCMs can lead to energy savings of up to 18.7% and CO₂ reductions of up to 15% for electricity and 38% for natural gas.

Space-saving

PCMs present superior thermal regulation without requiring bulky insulation layers. Using PCM in small house construction lets you effectively maintain space in a cosy environment; maintaining a building’s aesthetic appeal is crucial.

Cost Savings

Although it has high initial costs, it can be paid back by maintaining overall building energy efficiency and reducing operational costs.

Applications of PCMs in Residential Construction

You can integrate PCMs into various building components, such as

Wall Insulation

You can include PCMs in wall panels to moderate indoor temperature fluctuations. This can reduce dependence on heating and cooling systems. PCM-integrated gypsum boards improve thermal energy storage, regulate indoor temperatures, and decrease building energy consumption. Commonly used PCMs for wall insulation are paraffin wax and fatty acids. By adding PCM-included bricks, you can reduce annual energy consumption by 17.6%. Also, during the heating season, the impact of implementing PCM integrated bricks on energy conservation will be considerable.

Source: thermtest.com

Roof and Ceiling Systems

When you integrate PCMs into the roof, they help to maintain the coolness of the building. When most of the heat from the sun enters through the roof, PCMs on the roof (at the right placement) can reduce this heating effect along with the external need for cooling. This will help to enhance the building’s energy efficiency. Paraffin wax and Hydrated salts are commonly used PCMs in roofing.

Flooring Solutions

When you include flooring with phase-changing materials, they store heat during the day and release it at night, which is beneficial in extreme climates. You can go for PCM tiles or concrete mixtures for passive temperature control. Lightweight dense/porous PCM-ceramic tiles are commonly used to reduce indoor space temperature variation.

Windows and Glazing

For window settings, you can include PCM-filled glass units to improve insulation. This can be achieved by absorbing and releasing heat, reducing heat transfer through windows. Dynamic shading solutions using PCMs can control the amount of solar radiation entering a building, preventing convective heat transfer by absorbing heat. PCM glazing has been shown to lower interior air temperatures and reduce building heat gain.

Disadvantages of PCM in Residential Buildings

Although PCM offers several advantages, it also offers the following few disadvantages:

- Low thermal conductivity: PCMs transfer heat slowly. This can reduce energy storage efficiency over time.

- High Initial Costs: PCM-integrated building materials are more expensive compared to traditional building materials.

- Phase Separation and Degradation: Over a certain period of time, PCMs will undergo phase separation and degradation. Thus, it can lower their long-term effectiveness.

- Supercooling Problems: Inorganic PCMs such as salt hydrates offer supercoolness. The PCM does not solidify at the expected temperature, impacting performance.

To address these issues, PCMs demand proper encapsulation techniques, such as micro- or macro-encapsulation, to prevent leakage and ensure durability.

Considerations for Using PCM

Before incorporating phase change materials (PCMs), you need to consider the following major factors:

- Proper encapsulation is essential to control leakage of the PCM during phase transition, which can compromise its thermal properties and structural integrity.

- Always choose the appropriate PCM as per your local climate conditions; this will increase energy savings and maintain thermal comfort. PCMs with melting temperatures within the summer comfort limit of 25.5–30°C are suitable for hot-arid regions.

- Don’t forget to check its long-term durability and maintenance; PCMs can deteriorate over time because of repeated expansion and contraction, impacting their thermal stability and reliability.

- Always choose PCM depending on their melting temperature.

- The chosen PCMs should exhibit high chemical stability, non-toxicity, and compatibility with storage containers. Stable PCMs resist degradation and chemical reactions over many thermal cycles.

You can build a home with PCMs to help reduce heating and cooling costs. The PCMs can be integrated into walls or placed in pellets inside rooms. During warm periods, PCM boards inside the wall store energy due to hot air rising. The heat absorbed by the boards is discharged later during cold periods, warming up the air. Such systems are best fitting in countries where the nights are considerably colder than the days, like Rajasthan. In such places, PCMs on walls and roofs can melt and store large amounts of heat during the day. The heat is then released to the ambient at night, perhaps with the help of chillers, reducing peak-time electricity costs, which can be very high in some places. Brick & Bolt’s innovative approach to sustainable construction positions them perfectly to explore PCM integration in future projects, enhancing their commitment to energy-efficient building solutions. Their expertise in delivering quality homes makes them an ideal partner for implementing these advanced thermal management technologies as the building industry evolves.