Whenever you want to create a partition wall with or without vertical support to the wall, you can directly opt for stud walls. A stud wall is a lightweight, load-bearing or non-load-bearing framed wall used to split building interior spaces. It’s a partitioning system that can create adaptable layouts within wide spaces. Modern architecture also uses these walls to enhance the aesthetics of the space with acoustics.

Read today’s blog to learn more about stud walls.

What is a Stud Wall?

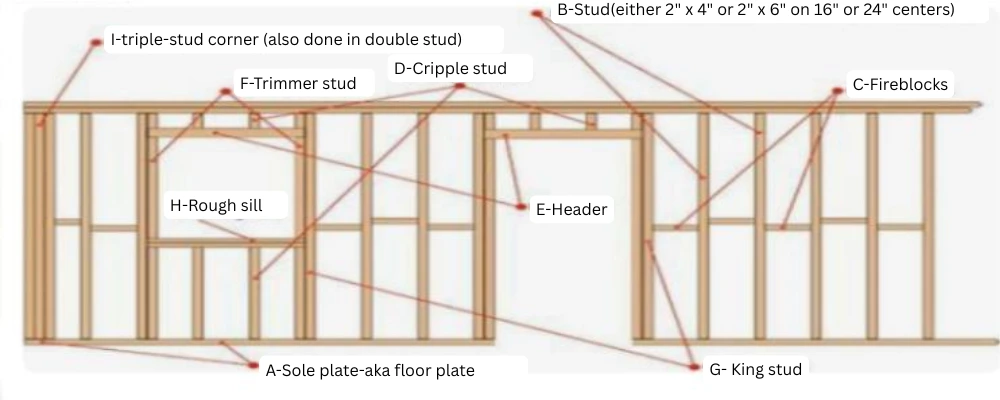

You can consider stud walls as internal walls supported by a wooden/metal frame against a solid wall. Commonly, stud walls are called framed walls. These walls include a simple procedure to set up. In these framed walls, the studs will be placed at regular intervals and are generally connected with horizontal panels at the top and bottom. These studs give vertical support to the main wall. You can also use these walls as partition walls.

Purpose of Stud Walls in Building Construction

A stud wall is a lightweight, non-load-bearing framed wall used to create partitioning between interior spaces in buildings. The following are the major purposes of using stud walls:

- Structural Support: Stud walls can offer vertical support to the building’s ceilings, floors, and roofs. They help to maintain the building’s structural integrity.

- Partitioning Spaces: Stud walls can be used to partition different rooms, spaces, or areas within a building. They enable flexible and efficient room layouts for a wide space.

- Concealing Services: Stud walls are a wise option to conceal electrical wiring, plumbing pipes, and other utilities. These utilities can be obscured within the stud wall cavities, allowing for a concealed and organised issuance of essential building systems.

- Insulation & Soundproofing: If you insulate stud walls properly, it can act as a soundproofing wall between rooms. This can be achieved by including insulation material within the stud wall cavities to reduce sound vibrations and thermal heat transfer. This way, you can improve acoustic privacy.

Types of Stud Walls Based on Composition

The following are the major types of stud walls based on the materials used to build them:

Timber/Wooden Studs

This is the oldest and most popular stud wall type used in homes. Common wood stud materials include teak, sal, Douglas fir, cedar, and pine. Wood is easy to saw, nail, drill, shape, repair, and maintain, so it’s the preferred choice for homeowners and professionals. You can also take this as a DIY project. A traditional wood stud wall typically uses 2×4 or 2×6 boards. It is widely used in residential construction due to its easy maintenance and affordability.

Metal Stud Walls

Metal stud framing is often made with galvanised steel or aluminium. Metal stud walls are commonly used in drywall partition systems. Since aluminium stud walls are lightweight, they are used in temporary and non-load-bearing partitions. These metal stud walls are fire-resistant and highly durable; thus, they are used in commercial buildings and high-rise constructions. Compared to wood studs, metal studs are less available. Standard metal studs are usually available in dimensions of 10 to 14 feet long and widths of 1-5/8, 2-1/2, 3-5/8, 4, and 6 inches.

Engineered Wood Stud Walls

Manufacturers specially prepare engineered wood studs to meet specific qualities. Although these are also made of wood, their qualities differ from actual wooden stud walls. This is because engineered wood studs can be made of various types of wood pieces, sawdust, chemicals, and adhesives.

These stud walls are easily available on the market and can bear heavy loads. However, engineered woods are vulnerable to fire, moisture, and pests. Engineered wood studs are available in all sizes as per your requirements.

Stud Wall Construction Procedure

Plan the Stud Wall:

Decide where you need to include the stud wall. Look for joists (wooden supports), electrical cables, and water pipes in the walls, ceiling, and floor. If your stud wall goes across (right angles to) the floor and ceiling joists, you can fix it anywhere. If your wall runs along (parallel with) the joists, it must be built directly above one of the joists for support.

If the stud wall needs to be installed between joists, You’ll need to add support:

- Lift the floorboards, both above and below.

- Fix wooden beams (100mm x 50mm size) between two nearby joists.

- Place these beams at 1-meter gaps to hold the new wall properly.

Framing Stud Wall

Floor Plate (Bottom Plate): Measure the intended length of the stud wall. If you’re adding it between two existing walls or adjacent to skirting boards, make sure the timber fits this space. After cutting, add this floor plate to the floor with nails evenly spaced at about 400mm intervals.

Ceiling Plate: Connect a plumb line or chalk line at the point where the wall touches the ceiling. Prolong this line towards the opposite ceiling, marking where the top of your new wall will meet. If nailing into a plastered ceiling, specify the ceiling joists first. Cautiously nail the timber in place, right along the chalked line.

Vertical Studs: Cut your vertical studs so they snugly fit between the ceiling and floor plates. If skirting boards are present, carve a notch in the studs for a flush fit. Secure your studs at regular intervals, ideally between 400-600mm.

Girding the Frame

You need to add noggings midway between vertical studs for added support and to hang heavy items. Leave a space if you intend to add a door frame. Secure the noggins with nails or wood glue.

Attaching the Plasterboard

Fit plasterboard sheets either vertically or horizontally, securing them with drywall screws at 150mm intervals. Cut plasterboard slightly shorter than the ceiling height and fit insulation before boarding the other side if required.

Stud Wall Insulation

You can insulate stud walls by filling the space within these frames with suitable materials to improve the sound- and fire-resistant qualities of the space that includes them. The following are the two popular insulations used within stud walls:

Fiberglass Insulation

This is the most common insulation type used for stud walls. It is the most affordable option and is easy to install. This insulation material will be made of fine glass fibres, which can minimise heat transfer effectively.

Spray Foam Insulation

Spray foam insulation builds an airtight barrier within the stud frames. These can effectively reduce heat loss and air infiltration. Thus, it is often used within stud walls to seal even the smallest cracks or holes and optimise thermal performance.

What are the Advantages of Using Stud Walls?

Cost-Effective: Stud walls are one of the budget-friendly partition options. They’re easy to install and remove. For value-conscious homeowners and DIY enthusiasts, this option works well.

Quick Installation: This option can reduce the overall project time compared to traditional masonry. These lightweight construction units are easy to assemble. It works well for modular homes.

Fire and Moisture Resistance: Stud walls made of metals often provide better fire resistance. Some specific sorts of plasterboards offer moisture-resistant properties. Wall partitions made of these materials can withstand humid environments without water damage.

Sound Insulation: As stud walls include multiple layers, they can act as a buffer in the space. Stud walls are made of wood or metal, and the panels within the wall hinder sound vibrations, thus reducing noise transmission. Properly sealing the wall frame with insulation material reduces sound effectively.

Stud Wall Cost in India

In India, timber studs typically cost between ₹200-₹400 per square foot, making them a budget-friendly option for smaller projects. Metal studs, often made from galvanised steel or aluminum, are priced higher at ₹300-₹600 per square foot but offer superior durability and resistance to moisture and fire. These costs are competitive compared to traditional brick-and-mortar walls, which are more labour-intensive and expensive.

Stud walls are commonly used in modular homes, offices, and for dividing rooms in houses. They are quick to install, which helps finish the work faster. Because they are thin, they also save floor space. You can add insulation inside them to keep rooms cooler or warmer, which is useful in India’s growing cities. You can hire an expert construction company or take on the project. For better efficiency its better to take support from experts.