Industrial and many types of commercial construction typically involve materials that are lightweight and can quickly be assembled to form enclosed spaces. A commonly used material for such construction is a PUF panel, whose widespread benefits have made it popular in the building industry across the world. Continue reading to learn all about the PUF panel meaning and components, PUF sheet manufacturing process, advantages and limitations and the PUF panel price in India.

What is a PUF Panel?

A Polyurethane Foam (PUF) panel is a type of sandwich panel consisting of two outer layers made of rigid materials sandwiching a core of polyurethane foam. PUF roofing sheets and wall panels are some of the most widely used types of sandwich panels, especially in industrial buildings. Large-scale structures can quickly be erected with the help of these panels.

Components of a PUF Sheet

Image source: Link

A PUF panel typically has three major constituents:

Interior and Exterior Layer

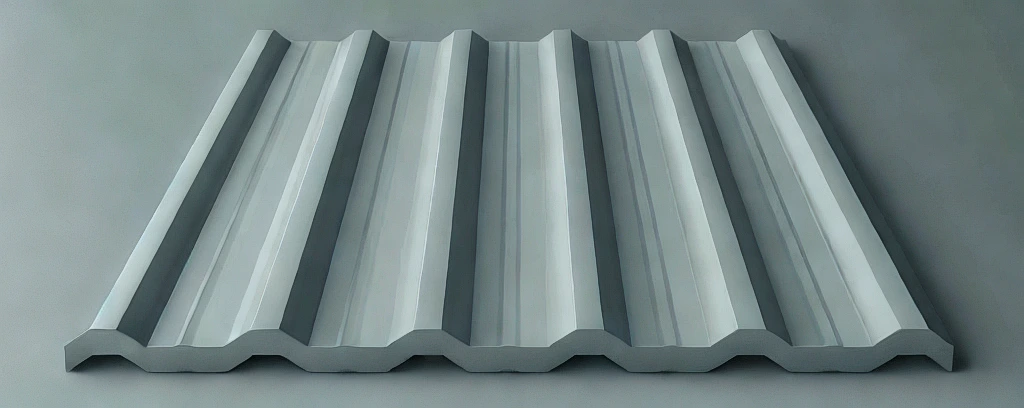

Two thin and rigid surfaces form the exterior and interior layers. Different materials like galvanised steel, galvalum, Oriented Strand Board (OSB), plywood and Fibre Reinforced Plastic (FRP) are used to make them. The exterior layer may have different profile designs (such as plain, corrugated or ribbed) and colours (which can generally be customised), while the interior layer is generally plain. The thickness of these layers range between 0.4mm and 1.2mm.

Core or Insulation Layer

The core layer made of Polyurethane Foam (PUF) has densely packed cells—which prevent the penetration of air and moisture—forming a lightweight material. PU (Polyurethane) is a type of plastic with excellent thermal properties, enabling PUF panels to provide enhanced building insulation. This layer has a thickness ranging between 20mm and 100mm.

Adhesives and Coatings

Adhesives bind together the different layers of PUF panels. These are commonly Polyurethane or epoxy resin based. Different coatings are provided for the exterior facing layers of a PUF panel to ensure its durability. Powder coating with Polyvinyledene Flouride (PVDF) or polyester-based sealants is generally done.

Apart from these major constituents, PUF sheets can also have additional elements to incorporate special characteristics like fire-resistance, microbial resistance and enhanced structural strength.

Properties and Advantages of a PUF Panel Sheet

- Strength-to-Weight Ratio: With very low weight, PUF sheets offer high strength and rigidity, allowing them to resist torsion, tension and compression. Lengths upto 12m can be spanned without any intermediary supports due to the high density of these sheets.

- Easy Installation and Dismantling: Installation generally involves only simple processes like bolting, welding, cutting and interlocking of adjacent panels. The panels can also be easily dismantled for replacement or reuse in other spaces.

- Thermal Conductivity: PUF panels have very low thermal conductivity values. They can reduce heat loss in winters and heat gain in summers, ensuring controlled indoor temperatures.

- Cost-Effective: Compared to conventional wall and roofing materials like Reinforced Cement Concrete (RCC) and brick masonry, PUF panels are much more cost-effective.

- Weather Resistance: PUF sheets are very durable and can withstand harsh weather conditions like prolonged exposure to extreme solar radiations and strong winds.

- Acoustic Insulation: With high sound absorption abilities, PUF sheets can avoid the formation of echoes in enclosed spaces. They can also prevent the entry of acoustic waves from exterior spaces, ensuring a soundproof nature.

Types and Applications of Sandwich PUF Panel

Types of PUF Panel

- PUF Sheet Roofing: PUF panel roof sheets are typically available with lengths between 1.2m to 12m, width 4m and thicknesses between 30mm and 150mm. These are installed on metal (or wooden) framed structures with the rafters having a minimum slope of 7%.

- PUF Wall Panel: This is generally available in thicknesses ranging from 50mm to 150mm and lengths between 0.9m to 12m (generally the width is a standard 1.2m).

Applications of PUF Panels

PUF sheets are commonly used in the following building applications:

- Industries that require large uninterrupted floor spaces for manual working and placement of machinery.

- Commercial buildings that need to be erected quickly to increase rental incomes.

- Warehouses and godowns that store goods at controlled indoor temperatures and humidities.

- Temporary structures that need to be built and dismantled in a short duration of time.

- Hospitals, spas and clean rooms where a controlled indoor air quality is required.

- Roofing structures for semi-open spaces like pergolas, balconies and gazebos.

PUF Panel Price

The common PUF sheet prices in India currently are:

- ₹1000- ₹1500 per sqm for galavanised aluminium PUF sheets with thickness between 30-100mm.

- ₹800- ₹1200 per sqm for PUF sheets with tin layers and thickness between 30-150mm.

- ₹1500- ₹2000 per sqm for galvanised steel PUF sheets with thickness between 30-150mm.

- ₹1500- ₹3000 per sqm for OSB (Oriented Strand Board) or plywood PUF sheets with thickness between 30-100mm.

The values mentioned above are only approximate and the actual PUF panel price per sq ft or sqm may vary widely based on the location, availability, brand, design, size, type and specific project requirements.

Limitations of Using PUF Panels

- Fire Resistance: Typically, PUF sheets are flammable, meaning that they can catch fire easily. However, fire-retardant types are now available, although these are more expensive.

- Behaviour of Joints: Joints between neighbouring PUF panels and between PUF panels and different structural members are tricky to waterproof. Especially in roofs, these joints can cause water leakage or seepage issues.

- Moisture Resistance: Even though PUF panels are precoated with paint, high levels of moisture can corrode the underlying layers. High salt content in the air (in coastal areas) can especially cause rusting and material degradation.

- Rigidity: PUF panel roofing sheets and wall panels are very rigid and generally available only in standard sizes. This significantly limits flexibility and design freedom, allowing only rectilinear forms to be built.

Constructing a PUF Panel House or Building

With multiple vendors, rates and types of PUF panels available in the market today, it can be intimidating to source these panels. However, Brick & Bolt—a tech-enabled construction company in India—collaborates with the leading manufacturers in the country to source top-quality materials at the best prices. This leading design-build company in India offers end-to-end construction services guided by the design of experienced architects and execution of qualified construction professionals. Reach out to Brick & Bolt today to ensure the use of the best quality PUF panels in your residential or commercial construction project today!