Various types of manufactured boards are being used in the modern AEC (Architecture, Engineering and Construction) industry as substitutes for natural wood boards. One such type that has gained popularity in the last decade is a particle board. Keep reading to understand exactly what particle boards are, their types, advantages and disadvantages, applications in buildings and learn the cost of particle boards in India.

What is a Particle Board?

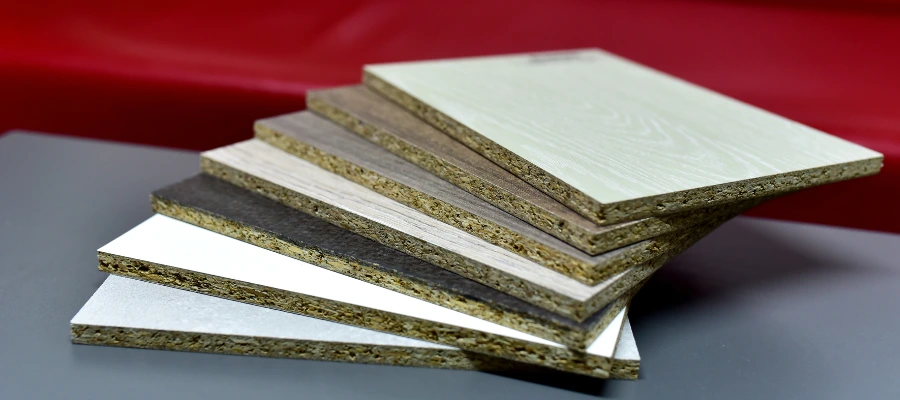

A particle board is an engineered wood product made with waste wood particles like chips, sawdust and fibres. For its manufacture, wood waste is fed into a chipper, which cuts them into uniform or similar shapes and sizes. They are then laid in a flat layer and resin is sprayed on them. Multiple such layers are then combined and compressed under high temperatures and pressure to form wood particle boards with moderate strength. These boards have numerous applications and are commonly used in building projects across the world.

Advantages of Using Particle Boards

- Lightweight: Particle wood boards are extremely lightweight. This makes their transportation and installation much cheaper and faster than solid wood and even other engineered wood products like plywood and MDF.

- Acoustic Properties: Due to their high density and uniformity, these boards have excellent acoustic properties. They are often used for soundproofing rooms or for improving room acoustics.

- Workability and Finishing: Engineered wood particle boards have a uniform appearance and can be easily machined or cut for specific purposes. Various finishes, such as paints, polishes, wood veneers and laminates, can also be easily applied to them to obtain the required finish.

- Sustainability: Typically made using waste products from the manufacturing process of other wooden products, these boards do not contribute to additional deforestation. Their reused and recycled nature thus encourages sustainable building practices.

- Cost: Engineered particle boards are one of the cheapest engineered wood products available in the market today. They can effectively be used to substitute solid wood in many non-structural applications, thus reducing construction costs and project budgets.

MDF Vs Particle Board

MDF and particle board are both engineered wood products and are often confused to be the same. However, there are multiple differences between their composition and properties, including:

| Property | MDF | Particle Board |

| Composition | Wood residuals like chips, fibres and shavings are converted to fine grains and then compressed to form MDF panels. | Wood residuals like chips, shavings and fibres of uniform sizes are directly mixed and compressed to form these boards. |

| Moisture Resistance | Higher resistance to moisture, does not easily warp, shrink or crack | Very low or negligible resistance to moisture, can easily shrink and warp |

| Weight and Strength | Higher weight, but has higher strength and load-bearing capacity | Lower weight with reduced strength, much lower load-bearing capacity |

| Durability | It can last for a minimum duration of 10 years without much degradation. | Lasts for around 2-3 years, lesser under extreme climatic conditions |

| Cost | Has a higher cost | Very cheap |

Applications of Particle Boards in Buildings

Building Components

- Flooring and Roofing: Due to their uniform surfaces and affordability, engineered wood and particle boards are used as bases for anchoring or fixing the final finishing materials (such as tiles, stone flooring or interior wall panels) on floors, walls and roofs.

- Doors: These boards are used to make composite doors that are lightweight and affordable, making them ideal for interior use.

Interior Design Components

- Furniture and Storage: Wardrobes, modular kitchen cabinets, tables, shelves, chairs and display units can be made with these boards. They can also be used as a base to lay kitchen countertops and other such shelving or storage units. Although they cannot bear heavy loads, they are lightweight, stiff and affordable for such uses.

- Partition walls: Due to their good workability and ease of finishing, these boards can be used to create partition walls with versatile designs.

Types of Particle Boards

Apart from the standard type, several other types of particle boards are available in the market today, including:

- Veneered or Pre Laminated Particle Board: A veneered or prelam particle board consists of an additional coating of laminates or wood veneers on the external surfaces. Apart from being more aesthetic, this board also has a better resistance to moisture.

- Cement Bonded Particle Board: In this board, cement is used as a substitute for or along with resins to bond the wood particles together. Such a pressed board is fire resistant, has better resistance to moisture and imbibes higher strength.

- Melamine Particle Board: Here, thin melamine sheets are bonded to the top, bottom or both the external surfaces of standard boards. While providing an enhanced resistance to water, these coloured particle boards are also versatile as they are available in multiple finishes.

- Single-Layer Particle Board: This board has a uniform density and the sizes of wood particles are also similar across its volume. Although it has high density, it is generally not water resistant.

- Three Layer Particle Board: It is made of three layers of wood particles, in which the external layers are compacted to have high densities and the core layer has bigger particles with a lower density. This type was developed to reduce the amount of resins used in manufacture while incorporating better strength.

Limitations of Particle Boards

- Strength and Load Bearing Capacity: Compared to other engineered wood products like plywood, MDF or Oriented Strand Board (OSB), these boards have much lower strength and cannot be used in applications that need heavy load support.

- Moisture Resistance: These boards do not have good resistance to moisture, which can especially be noticed in regions with warm and humid climates. Even with slight moisture, most types can undergo warping, swelling and failure.

- Risk to Wellbeing: The production and use of these boards results in the emission of chemicals like formaldehyde which are used in their resins. With prolonged exposure, particle boards can be seriously harmful to humans and cause health issues.

Particle Board Price

Common particle board sizes are 4’ x 8’, 3’ x 7’ and 2’ x 6’. The cost of particle boards varies in different locations of India based on factors like type, panel size, thickness, brand and market trends. For example, the 18mm particle board price will be much higher than the 12mm particle board price as it has higher strength and stability.

Some of the common prevalent rates are as follows:

| Type | Thickness (mm) | Particle Board Price Per Sq Ft (₹) |

| Standard Particle Board | 6 – 25 | 10 – 80 |

| Veneered or Laminated Particle Board | 6 – 25 | 30 – 120 |

| Single Layer Board | 6 – 25 | 15 – 80 |

| Melamine Particle Board | 6 – 25 | 25 – 100 |

| Cement Bonded Board | 6 – 25 | 40 – 150 |

Buying and Using Particle Boards in Construction Projects

Since they are extremely affordable and have good workability, particle boards are some of the most commonly used wood products in building projects. However, procuring the right type and quality can often be difficult due to the presence of numerous brands and suppliers in the market. Leading construction companies like Brick & Bolt offer end-to-end construction services along with the supply of top-quality building materials by joining hands with reputed brands and manufacturers in India. To ensure that your dream building project is completed by using premium materials, get in touch with Brick & Bolt today!