As the global need for new infrastructure increases, natural aggregates have become the primary resource needed to meet this high demand. These aggregates can be found in the ground and are crucial in the manufacture of materials used in building construction.

The blog gives a complete description of natural aggregates, their variety, importance, uses, advantages, and criteria for choosing the most suitable material.

What are Natural Aggregates?

Natural aggregates are those compositional particles that are acquired in the natural state from rock types of the quarry, either by mining, smuggling, or by mechanical processing.

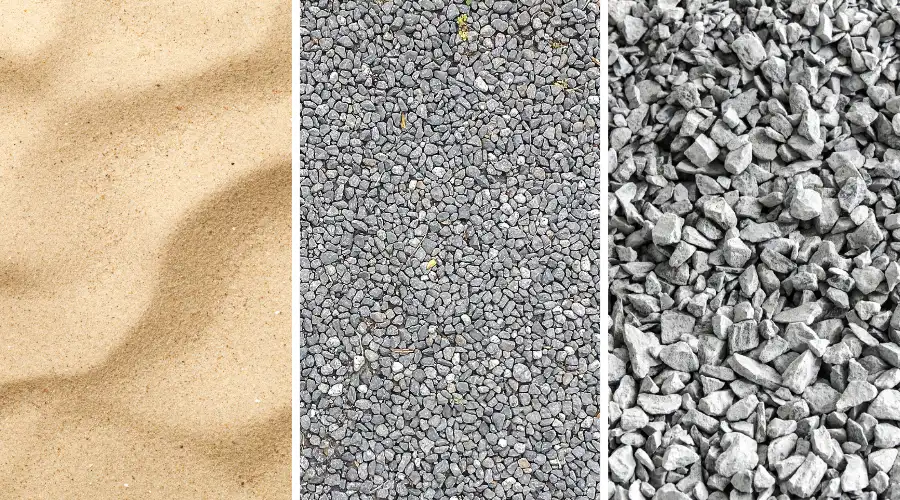

These materials, like crushed stone, sand, and gravel, are indispensable in the construction industry to produce concrete, asphalt, and other construction materials. Unlike the recycled or machine-made ones, they are the direct extraction from the planet, so they keep their natural mineralogical and physicochemical properties.

The mineral composition in most cases consists of quartz, feldspar, and calcite, which is responsible for the products’ strength, permanence, and elastic attributes. Natural aggregates work in this way. They provide the backbone of the construction sector with attributes like sustainability and strength once they have been used for infrastructure development and building projects alike.

Types of Natural Aggregates

Natural aggregates are categorized based on their quality, mineral composition, and particle size. The following classes represent the main types of natural aggregates.

1. Sand

Sand is defined as a fine aggregate that falls in the range of 0.075 mm to 4.75 mm. Sand is predominantly silica or quartz and is produced from river bottoms, beaches, or quarry sources. Sand is essential in concrete, mortar, and plaster for its binding strength and ease of application.

2. Gravel

Gravel is a coarse aggregate with particles (or stones) invariably larger than 4.75 mm and regularly up to 75 mm. Gravel can be sourced commercially from river bottoms, glacial deposits, and quarry sources. Gravel is advantageous when used in the production of concrete and construction of roads (subbase or surface) and drainage, due to their high load-bearing capacity and permeability.

3. Crushed Stone

Crushed stone is created when large blocks of rock (limestone, granite, or basalt) are mechanically broken down into aggregates of various sizes and shapes that can be used for a variety of applications, including road bases, railway ballast, and structural concrete. The strength and angularity of crushed stone are superior to those of natural gravel.

4. Other Natural Aggregates

Other types of natural aggregates include,

- Slag (natural slag quality)

- Natural lightweight aggregates (pumice, scoria)

- Marine aggregates (sea-dredged aggregates)

Use in specialty construction applications requiring desired properties (low density, resisting chemical attack).

Importance of Quality in Natural Aggregates

- Structural Integrity: Aggregates of good quality will maintain the strength and durability of construction materials like concrete and asphalt, and this, in turn, will prevent the appearance of cracks and the failure of these materials.

- Mineral Composition: Rocks with quartz and other minerals that are extracted by aggregates are the key behind the strength and resilience of construction materials.

- Consistent Grading: The correct size of particles assures both solid mixture properties and the ability to better compact, workability, and achieve bonding strength while providing a uniform and stable product.

- Reduced Risk of Defects: Impurities or irregular particle sizing can result in problems such as cracking, shrinkage, or erosion, which can have a negative impact on the structure over time.

- Environmental Resilience: By the use of high-quality aggregates, the material becomes more susceptible to the environmental effects and therefore more resistant to weathering, freeze-thaw cycles, etc. In this way, durable infrastructure is obtained.

- Industry Standards Compliance: It is of utmost importance to the performance of construction materials and structures that the aggregates used are subjected to rigorous testing and come from reputable sources.

Properties of Natural Aggregates

The composition, structure, and properties of materials affect the behavior and performance of the construction objects.

1. Specific Gravity: The higher the specific gravity, the good quality aggregates. Normally, the range is from 2 to 3.

2. Bulkage: It is a volume change in aggregates caused by the added moisture content. Bulking in sand typically ranges between 20% to 30%, while in coarse aggregates, it is generally negligible.

3. Voids: The space between particles; well-graded aggregates fill the voids and thus maintain the mass of particles, increasing the stability.

4. Size and Shape: Aggregates smaller than 4.75mm are classified as fine aggregates, while those larger than 4.75mm fall under coarse aggregates. The dimensions and form of these particles play a significant role in determining the concrete’s strength and longevity. However, using larger aggregates may reduce the workability of the concrete mix.

6. Texture: The aggregates of rough texture lead to good bonding with cement; thus, the strength of the mixture increases.

7. Porosity: Aggregates with high porosity tend to be less dense and structurally weaker, making them more susceptible to crushing under load. This can adversely affect the overall strength and durability of concrete.

8. Water Absorption: Excessive water absorption by aggregates can lead to increased moisture in the mix, which may result in shrinkage cracks as the concrete dries. This compromises the integrity and longevity of the structure.

These features are the deciding factor of the action of concrete, showing the high impact of quality natural matter on the resistance of the building.

Uses of Natural Aggregates in Construction

Natural aggregates are important in many construction activities, including the following,

- Concrete production: Aggregates comprise 60-75% of the volume of concrete, contributing to its strength and stability.

- Road construction: A wide variety of aggregates can be used for the base or sub-base and surfaces of roads/highways and pavements.

- Railway ballast: Crushed stone is the only choice for railway ballast in that it provides both stability and drainage.

- Drainage: Gravel and sand are both commonly used in drainage.

- Masonry and plastering: The fine aggregates (sand) are used in mortar and plaster mixes.

Natural aggregates are reasonable, available, and versatile, all of which make them the first choice for construction, and this for activities both small and large.

Benefits of Using Natural Aggregates

Natural aggregates have multiple benefits,

- High performance and durability: They improve the physical properties of concrete and asphalt.

- Low cost: Naturally occurring aggregates are usually more available and less expensive than manufactured aggregates.

- Widespread application: They are heavily used in all types of construction work.

- Consistency: Well-graded natural aggregates ensure the products made are uniform.

These numerous benefits of natural aggregates embody why they are still a heavily utilized material in modern construction.

Factors to Consider When Choosing Natural Aggregates

The choice of the right natural aggregates is highly important when it comes to the implementation of concrete in building construction, which is strong and durable as well as sustainable. Some of the main factors to consider are,

- Source and Availability

Use of nearby aggregates is the solution for multiple problems: lower transportation cost, lower the impact of transportation (thus, the environment), and no project delays. Proximity to the site gives the assurance of an uninterrupted flow of supply, and on the other hand, cuts carbon emissions.

- Physical Properties

Particle size, shape, surface texture, and grading affect the workability and strength of concrete. If the particle is well-graded then the voids are less and the cohesiveness is more. Also, the role of the angular parts is to strengthen bonding.

- Chemical Stability

Aggregates should be chemically inert and must not react with alkalis, sulfates, or chlorides present in the cement or environment. Reactions like alkali-aggregate reaction (AAR) can cause expansion, cracking, and long-term deterioration of concrete, compromising its durability and structural performance.

- Environmental Impact

The point of impact is the sourcing process, which has links to environmental issues such as habitat destruction, soil erosion, and loss of biodiversity. Environment-conscious extraction methods are those that are gentle and leave the area looking more or less untouched.

- Compliance with Standards

Aggregates that have passed through the national and international standards, like IS383:2016, ASTM C33, etc., are the ones a consumer can rely on in terms of uniformity, quality, and performance.

- Durability

Aggregate materials should be able to resist weather conditions such as those experienced during the freeze-thaw process and remain abrasion-free, thus ensuring long life to concrete.

By considering the above, you have a better chance of gaining better performance, durability, and serviceability in your construction projects.

Conclusion

Natural aggregates continue to provide unrivaled strength, durability, and versatility as an integral component of construction. Selection and quality of aggregate will be directly related to the success of an infrastructure project. The key to identifying aggregate types, uses, benefits, and selection is to empower the professionals to make decisions that will support safety, sustainability, and cost-effectiveness related to construction endeavors.