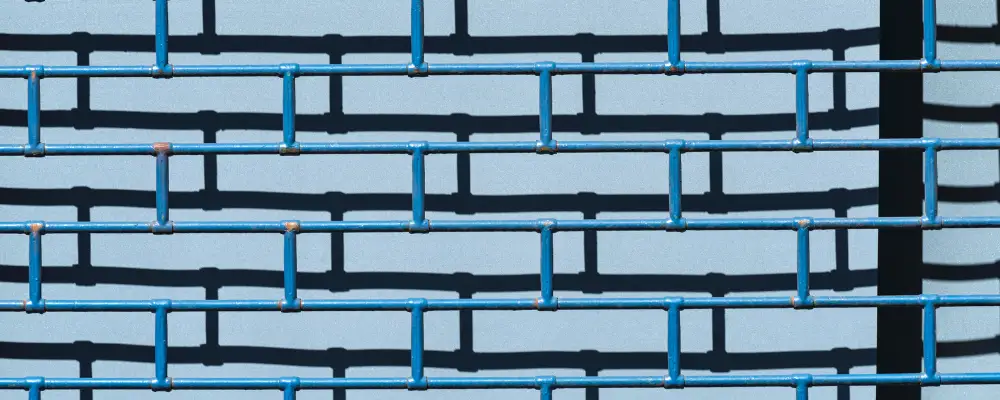

Mivan shuttering is a highly sought-after formwork technique in today’s construction sectors. It is commonly used for slab casting, stairs, columns, walls, etc., with a seamless process. The major key components of Mivan shuttering materials are aluminium sheets, wedges, pins, props, panels, etc. All the components work together to create an effective Mivan shuttering system.

Across the globe, most of the civil engineers and constructors prefer Mivan construction for an effortless and smooth shuttering process. Do you want to know how it works and why it is important? Read the content below to get more insights.

The Basics of Mivan Shuttering

Mivan Shuttering is an aluminium formwork that provides support and strength for building concrete. It helps to speed up the construction and avoid lapses. There are different types of formwork used in Mivan shuttering, and each type varies in cost and quality. Indeed, tall or height-based buildings, such as apartments and towers, primarily utilise this formwork.

Why Does Mivan Shuttering Matter?

Though there are several formworks available, mivan shuttering is preferred for its speedy, quality, and efficient concrete construction. The accuracy and durability of this method make it common in large-scale projects and mass housing areas. The reasons why mivan shuttering stands out are discussed below.

Premium Finish: The precision-engineered aluminium panels give smooth and uniform concrete surfaces. This reduces or avoids the need for the plastering process, thus saving time and cost.

Faster Construction: When compared to traditional formwork, mivan shuttering saves floor construction time by almost half. So, it is easy to do slabs frequently, i.e., every 7-9 days, and meet even tight schedules.

Monolithic Strength: Since walls and slabs can be cast together in a single pour, the final result will be seamless and have high seismic resistance.

High Precision & Accuracy: The factory-made panels facilitate accuracy in dimensions and result in structural consistency so that human errors can be reduced.

Cost-Effective for Big Projects: Yes, the initial setup for mivan shuttering is expensive. But the reusable nature of the formwork makes it economical for repeated and larger projects.

Parts of Mivan Shuttering

In the Mivan Shuttering process, various parts are used to do the formwork. Each part is meant for meeting unique needs. Some of the commonly used parts are listed below.

- Concrete Wall Panels: These aluminum panels are used to form the vertical walls of the structure. They are usually lightweight, long-lasting, and shaped to make accurate casting without extra finishing.

- Beam Panels: These panels are placed in a horizontal manner to cast beams without slabs and support the concrete for structural framing.

- Deck Panels: To form the floor slabs, these flat horizontal panels are positioned on top and supported by props until the concrete sets.

- Beam Bottom Panels: Placed beneath the beam panels to support them while concrete is poured and to achieve an even finish.

- Props and Prop Heads: Provide vertical support for deck panels and maintain the desired height during casting. Prop heads are used to connect props to the panels securely.

- Pins and Wedges: These are locking parts that connect different panels together for tight joints and accurate alignment.

- Kickers: A small part used to align the wall panel at the bottom and maintain form.

- Tie Rods and Wall Tiles: These parts help to hold opposite panels together by resisting the pressure from unset concrete and preventing any misplacement.

Working Procedure of Mivan Shuttering

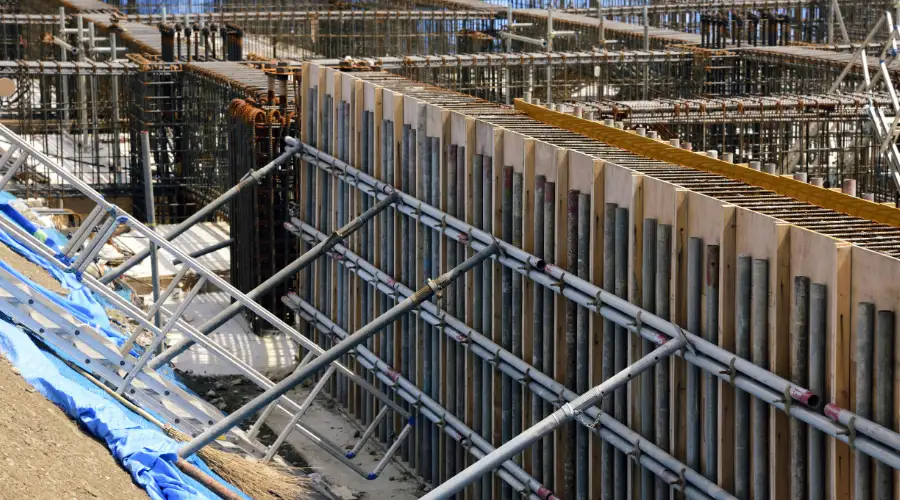

The Mivan shuttering process begins with precise planning and measurement based on the building’s structural design. The aluminium formwork system is then pre-cast and custom-manufactured in a factory, tailored to the specific layout of the construction project. These pre-fabricated panels include wall, slab, beam, and column components.

At the construction site, wall reinforcement steel is placed first. Then, the formwork panels are assembled to encase the reinforcement, forming the mold for concrete pouring. The system includes pins, wedges, and other locking components to secure the formwork tightly.

Once the formwork is in place, concrete is poured. After 12–24 hours (depending on the mix and weather conditions), the formwork is de-shuttered and reused for the next cycle. Mivan formwork is known for its rapid construction capabilities, allowing for one floor to be completed approximately every 7 days. Each formwork set can be reused up to 200–250 times with proper care and handling, making it highly efficient for large-scale, repetitive construction projects like high-rise residential buildings.

Advantages and Disadvantages of Mivan Shuttering

Advantages of Mivan Shuttering

- Faster Construction: Mivan shuttering speeds up the construction, which is ideal for high-rise projects.

- Premium Quality: The final appeal of the construction is high quality finish with unified concrete surfaces.

- Reusable: Mivan shuttering formwork can be reusable, unlike other techniques. The reuse of the formwork is up to 250 times.

- Reduces Labour Dependency: Mivan shuttering requires minimal labour work when compared to conventional methods.

Disadvantages of Mivan Shuttering

- High cost: Initially, the Mivan shuttering formwork costs more, and this method is not suitable for small projects.

- Challenges in Transportation: It seems difficult to move Mivan shuttering formwork panels from one place to another.

- Professionalism: The local engineers cannot process this technique because it has professional and standard procedures to install; therefore, an expert is mandatory.

Mivan Shuttering: Where It Works Well?

Mivan shuttering is widely used in various building projects, especially apartments, towers, and tall buildings. For example, high-rise residential projects implement the Mivan shuttering technique because it reduces labour time and provides structural strength, consistency, and high durability.

Mivan shuttering is effective in building with multiple units and is best suitable for railway stations, public buildings, hotels, airports, etc. The purpose of applying Mivan shuttering in these places is that it enhances the buildings’ construction speed, quality, and longevity.

Pricing of Mivan Shuttering

Pricing of Mivan shuttering varies according to the building projects, such as houses, schools, apartments, airports, hotels, etc. Each project has its unique price fixation, where Mivan shuttering is highly suitable only for large-scale constructions.

The industry price range of aluminium Mivan shuttering is approx. ₹800 – ₹1200 per sqm and ₹60-₹110 per ft. Also, Mivan shuttering is available for rent at a cost based on the days of usage. Furthermore, the pricing may differ based on brand, engineers, techniques, quality, type of projects, etc.

Mivan Shuttering vs Regular Formwork: A Comparison

| Features | Mivan Shuttering | Regular Formwork |

| Construction Speed | 7 days approximately per floor | 20 to 25 days per floor |

| Surface Finish | Smooth & Uniform (without plastering) | Uneven, so plastering required |

| Formwork Planning | Need detailed pre-planning | Basic planning is sufficient, as adjustments can be done on-site. |

| Type of Structure | Monolithic (means walls and slab cast together) | Usual RCC frame with separate casting |

| Material Work | Very low (as precision components are used) | High (as it involves cut and fit processes) |

| Labor Requirement | Less (even semi-skilled labour is enough) | High (needs skilled carpenter and masons) |

| Reusability Range | 200-250 times per panel | Limited usage (20-30 uses) |

| Seismic Resistance | Excellent (consistent casting improves stability) | Moderate (joints reduce integrity) |

| Level of Accuracy | High precision | Depends on workers effort |

| Dismantling Without Removing Props | Possible with modular design | Less or impossible |

Final Thoughts

The Mivan shuttering technique is widely used to accelerate various construction work. It is ideal for repetitive work and high-volume projects. The Mivan shutter doesn’t require more labourers to structure the alignment, which is one of the greatest advantages of this technique. This modern evolution demonstrates the significant advancements in constructive techniques, resulting in a premium-quality building finish and offering a perfect structural finish.

The Mivan shuttering enables builders to make informed decisions for their future projects while ensuring a proper investment. If you are planning to invest in a cost-effective technique for your mega projects, then choosing Mivan Shuttering would be a perfect choice to optimise construction efficiency.