Innovations in the building industry have led to the development of various new materials that are significantly changing the construction process and providing alternatives to conventional materials. One such material is glass fiber reinforced polymer, whose unique attributes have made its use widespread globally. Keep reading to understand exactly what glass fiber reinforced plastic is, how it’s made, types of GRP, its applications in the construction industry and the advantages and disadvantages of using GFRP in buildings.

What is GRP?

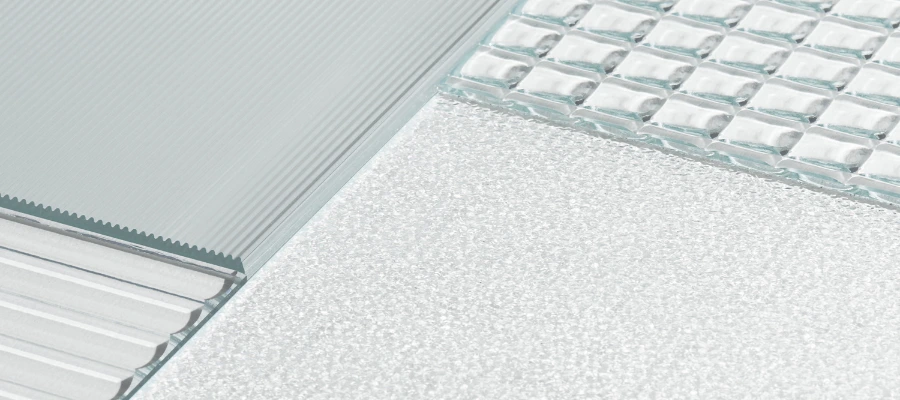

Glass fiber reinforced plastic (GRP/ GFRP) is a type of plastic that combines glass fibers with polymer matrix resins. Commonly known as fiberglass reinforced polyester or glass reinforced polymer, this material combines the best qualities of glass and plastic (such as strength and lightweight nature). With the addition of glass fibers, this FRP variety has extremely high strength and stiffness, enabling it to be used in both structural and non-structural applications in the modern construction industry.

How is Glass Fiber Reinforced Plastic Made?

The production of GRP material typically follows the below steps:

Raw Material Preparation

The main raw materials involved in making GFRP are:

- Resins: These are generally thermosetting or thermoplastic resins like polypropylene, epoxy, vinyl ester, polyester or polyethylene. They act as adhesives between the different components.

- Glass Fibers: Fibers in different forms such as woven mats and chopped strands are prepared by melting, cutting or subjecting glass to heat/ chemical treatments.

- Additives: Based on the requirement, various additives like colouring pigments and/ or chemicals for increasing strength or fire resistance may be used.

Manufacturing Process

GFRP material can be manufactured by different processes, including:

- Pultrusion Method: Here, the glass fibres are passed through a resin bath where the components are bonded together. They are then cured and cut into the desired shapes.

- Moulding Method: Dry glass fiber stacks are placed in moulds, into which resins are then injected. This method is ideal for producing complex GRP shapes.

- Hand Lay-up: Glass fiber mats are manually coated with resin layers and poured into moulds before curing in this method. It is cost-effective, but time-consuming.

Curing and Finishing

The curing process involves the hardening of the GRP material from a molten state to a stiff product. Curing can be done by subjecting the material to intense heat or chemicals that initiate the hardening process. It may also involve adding colouring pigments or other additives if needed. The material is then cut and finished to the required shapes and sizes.

Types of GFRP Used in Construction

Several types of glass fibres can be used in making glass reinforced plastic, affecting its strength and properties. These types include:

- E Class Fiber GRP: This has high electrical resistance and strength, and is most commonly used in construction applications like reinforcing concrete.

- A Class Fiber GRP: Has high alkali resistance and moderate strength, is generally used for making window glass panes.

- C Class Fiber GRP: Has very high corrosion resistance, but low strength, making it ideal for plumbing applications.

- S Class Fiber GRP: Has extremely high strength and is used in making load-bearing structures and framing members like beams and columns.

Advantages of GRP in Construction

- Strength-to-Weight Ratio: With extremely low weight, glassfiber reinforced plastic offers a tensile strength that is comparable to mild steel and aluminium. It is around 70% lighter than steel and 30% lighter than aluminium.

- Corrosion Resistance: GFRP is highly resistant to corrosion and chemicals. It can bear high salt content in regions with warm and humid climates without experiencing any degradation.

- Insulation: Glass reinforced plastic is a good thermal, electrical and acoustic insulator, making it ideal for many building applications.

- Water Resistance: GRP products are waterproof and can also resist high temperatures without melting when subjected to the right treatment. This makes it superior to other plastic varieties used in the construction industry.

Applications of Glass Fiber Reinforced Polymer in Construction

- Roofing: Glass reinforced plastic sheets are used to form roofs that are lightweight, weather proof and transmit maximum natural light into spaces.

- Water Retaining Structures: Since it is waterproof and chemical-resistant, GRP is used to build retaining structures that hold water or chemicals.

- Wall and Ceiling Panels: GRP sheets and panels are used for exterior wall cladding as well as interior wall and ceiling panelling because they are lightweight and durable.

- Pipes and Plumbing: Pipes and plumbing fittings made of GFRP are waterproof, lightweight, strong and corrosion resistant.

- Staircase Components: Intricate handrails and balusters with diverse profiles can be made with GRP for staircases.

Limitations of Using GRP in Construction

- Impact Resistance: GRP is a brittle material that can break upon sudden impact. Therefore, it is not ideal for use in spaces that experience high amounts of point loads or unexpected stresses.

- Repair: GFRP products can generally not be repaired in case of any breakage or damage. Even if repair is possible, it can often be expensive as it requires advanced machinery and extremely skilled labour.

- Environmental Concerns: The manufacturing process of GRP involves many chemicals that are toxic or harmful to the environment. This is against safe and sustainable building practices.

Using GRP/ GFRP in Your Construction Projects

The benefits of using glass fiber reinforced plastic far outweigh its limitations for most types of projects. However, its use in India is still limited due to lack of awareness and expertise regarding the material. Brick & Bolt, a pioneering tech-enabled construction company in India, endeavours to always incorporate innovative new materials in its projects. With a vast network of contractors, completely organised building materials supply and a patented system of quality checks (QASCON), the company has become a leader in the industry. Reach out to Brick & Bolt today to be sure that your home or commercial building is built with the best new materials like GRP!