Exhaust fans are generally the main source of ‘natural’ ventilation in enclosed spaces. Such fans not only expel stale air, but also moist air and odours, which are the main causes of indoor air quality degradation. The comfort level of any environment — residential, commercial buildings, or industrial — is also raised with the use of exhaust fans. This guide details out technical aspects of exhaust fans, including their working principle, installation methods, different ducting arrangements, relevant factors for performance, and sound control.

Overview of Exhaust Fans

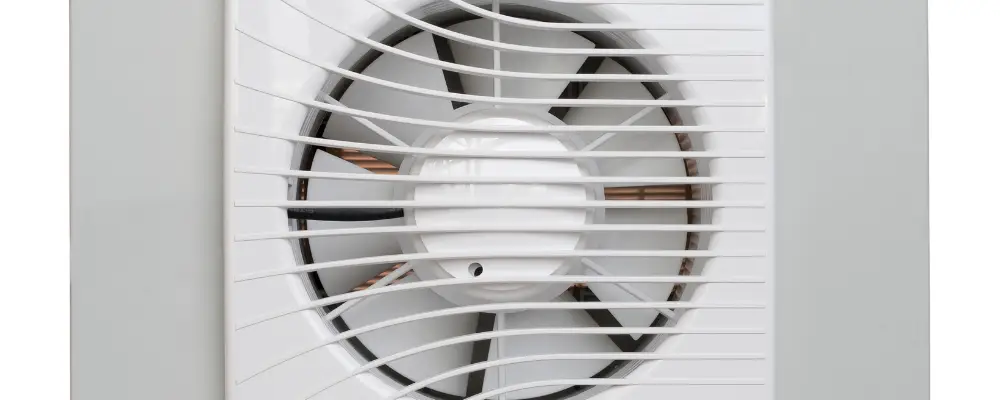

An exhaust fan is an equipment that, by creating negative pressure in a space or building, gets rid of hot, humid, or contaminated air and draws in fresh air from the outside. Consequently, exhaust fans find their utility in rooms with the highest pollutant levels – i.e., in moist rooms, spaces that are the source of cooking odors, or areas that may contain chemical fumes. The most common areas where they are used are bathrooms, kitchens, and industries. These fans consist of critical components like the motor, the impeller or blades, housing, and the electrical system. The motor powers the blades that spin at high speeds to produce airflow. The housing is vital for encompassing the motor, impeller, and blades, and guides the airflow efficiently.

Difference Between Exhaust Fans and Ventilation Fans

Although both exhaust fans and ventilation fans serve the purpose of improving indoor air quality, they operate differently:

| Feature | Exhaust Fan | Ventilation Fan |

| Function | Expels stale air and contaminants from indoor spaces | Circulates and refreshes air within the space |

| Airflow Direction | Outward (expels air) | Circular (creates airflow using the air already present in a room) |

| Application | Spaces that generate odours, hot air, moisture or contaminants | Spaces that need cooling |

| Purpose | Removes moisture, odours, and pollutants by introducing fresh air | Improves air circulation and cools spaces |

Components of an Exhaust Fan

- Motor: The motor is the powerhouse of the exhaust fan and changes electrical energy to mechanical power to spin the fan blades.

- Fan Blades: The blades are the basic element of the fan’s operation as they suck the used or stale air from the room and expel it outside, thus maintaining the airflow and ventilation.

- Duct Collar: This part attaches the fan to the ventilation duct, hence ensuring that the air is efficiently taken out of the room through the duct system.

- Backdraft Damper: This door or flap, which is at the back of the exhaust fan, shuts closed when the fan is turned off, thus ensuring that no outdoor air can enter the room.

- Housing: The housing is the body that holds and covers all the internal parts. It is used to fix the fan on the ceiling or the wall, and is securely installed with the bracket.

- Grill: The grill is the cover of the fan that protects internal components while allowing the airflow to be uninterrupted, thus ensuring efficient operation.

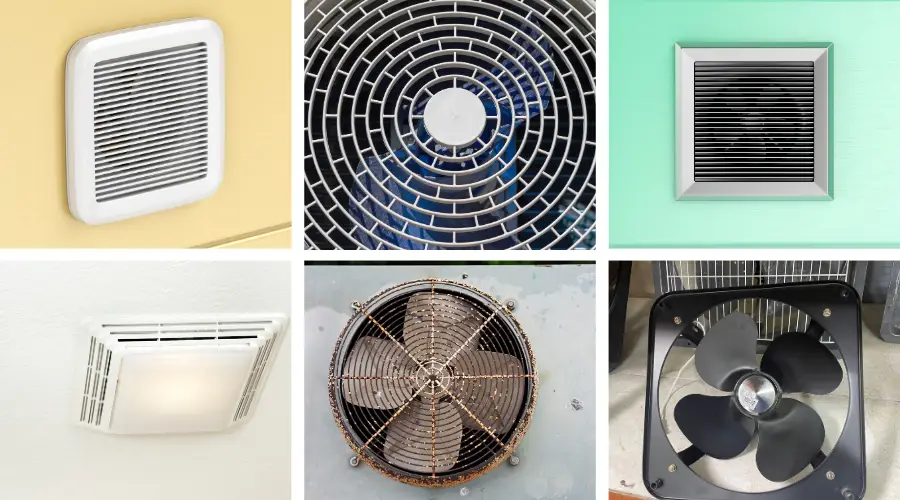

Types of Exhaust Fans

- Ceiling-Mounted Exhaust Fans: Ideal for enclosed spaces such as halls, lobbies, and cinemas, ceiling-mounted fans are installed in the ceiling and connected to a duct system that expels stale air outside. These fans are aesthetically pleasing and space-efficient.

- Wall-Mounted Exhaust Fans: Typically used in residential settings like kitchens and bathrooms, these fans are mounted on walls and are effective for spaces that require direct exposure to the outside. They help in improving airflow and removing odors and moisture.

- Duct-Connected Exhaust Fans: Also known as inline exhaust fans, these powerful blowers are integrated into ventilation systems and use ducting networks to expel large amounts of air. They are efficient for larger areas requiring high ventilation rates.

- Roof Exhaust Fans: Installed on rooftops, these fans are used in industrial settings or factories to expel hot air and moisture, maintaining a comfortable indoor environment.

Exhaust Fan Duct Materials

The ducting system is very important to make the exhaust fan efficient. The materials utilised for ducts and how the ducts are configured will affect the airflow and the fan’s overall performance. Here are some of the common materials used to make ducts:

1. Galvanised Steel

Galvanised steel is a very durable material that resists rust. Since it is so durable, galvanised steel can be used for long-term installation in both residential and industrial applications. The surface of the galvanised steel ducts helps lower resistance to airflow and thus increase overall efficiency.

2. Aluminum

Aluminum ducts are lighter and more corrosion-resistant, making them suitable for residential applications. They are easy to handle and install, but may dent or be damaged if handled improperly. Aluminum composite panel ducts are frequently used for exhaust fans in bathrooms and kitchens, where flexibility and ease of installation are the primary considerations.

3. Flexible Ducts

Flexible ducts are commonly constructed of aluminum foil or a similar material, and are great for low structural volume and/or highly flexible layouts, especially in residential construction projects. A flexible duct is inherently more restrictive to airflow than rigid ducts, and therefore will yield less overall efficiency.

4. Insulated Ducts

Insulated ducts are intended to reduce heat loss and condensation in HVAC System, and therefore may be suitable in areas with excessive moisture. They are applicable in kitchens or bathrooms, where uncertainty regarding temperature ranges — which can potentially reduce the yield performance — is common.

Design & Planning for Exhaust Fans

A proper design and planning process is important to ensure that an exhaust fan system is performing as well as possible. A properly designed system requires several important steps that need to be carefully followed before installation:

1. Calculating the Required Airflow

The airflow requirement for a room is typically measured in terms of Air Changes per Hour (ACH). It depends on the volume of the room and its intended use. For example, a small bathroom may only require a small ACH while a commercial kitchen might require several hundred ACH. To determine the ACH required, the formula is as follows:

ACH = CFM x 60 / Room Volume

Here:

- CFM= volume of air in cubic feet per minute

- Room volume= length x breadth x height of room, specified in cubic feet (cft)

This formula ensures that you can change the room air at an adequate rate.

2. Selecting the Appropriate Fan Size

To determine the fan size, you have to consider the required ACH and the pressure characteristics for the ducting system. Make sure that you pick the size of fan that meets the requirements of the room without being too large (which would create excessive noise and not be visually pleasing) or too small (which will not create sufficient ventilation). Fan suppliers usually have charts or guidelines on selecting fan sizes based on the volume of the room, as well as required ACH.

3. Strategic Placement of the Fan

The best location of the fan is going to be right in the area that is the source of moisture, heat, or odor. For example, in kitchens, the fan may need to be closest to where the stove is; in bathrooms, it may need to be just outside the shower door or the toilet. The closer the fan is to the source of contaminants, the faster these contaminants can be removed from the room.

4. Duct Sizing and Routing

Ducting takes time and can cost significant money. In general, the diameter of the duct should match the specifications for the exhaust fan and maintain sufficient airflow. The ducting should be laid out with as few bends/twists as possible to minimise airflow resistance (i.e., straight, short, not twisted or paused). Each bend and twist in the ducting increases resistance, and if you turn the duct too many times, you reduce the air-exchanges and lose airflow, thus creating inefficiencies.

5. Duct Configuration

The type and orientation of ducts (diameter, length, and the number of bends) can impact the operational performance and efficiency of a fan. The shortest, straightest ducts with the fewest bends will create the least resistance to airflow. Longer or more bent ducts will resist airflow and negatively impact fan performance.

Installation Process of Exhaust Fans

Exhaust fan installation is a detail-oriented task. The installer’s process should address safety and performance, as well as compliance with local codes. The basic procedure is as follows:

- Selecting the Installation Location: The fan location should be close to the moisture, odor, or heat source. The fan should be mounted in the highest position to maximise performance and efficiency.

- Cutting the Opening: Once the fan location is determined, cut an opening in the wall or ceiling (depending on the location of the fan) to the right size to accommodate the housing of the fan. When cutting the opening, measure carefully, as it is important that the fan can be mounted securely and avoid voids around the fan housing.

- Mounting the Fan: The fan housing should be securely mounted to the building member using screws or mounting brackets. Ensure the mounting is level and properly oriented towards the duct pipe.

- Connecting the Ductwork: Connect the ductwork to the fan, exteriors and to the electrical source. Ensure that the ducting route is as short as possible and that there are as little bends as possible.

- Electrical Connections: Connect the duct to the fan exhaust and route it through the wall or ceiling to an exterior vent. It is important to check that the duct installation includes proper sealing to prevent air leakage. The effectiveness of the exhaust fan, and potentially household safety, relies on the fan performing accurately, and air movement is a key tenet to its function.

- Testing the System: Once the fan is installed, it should be tested for proper operation. Check for smooth airflow, noise levels, and any potential leaks in the ducting system.

Noise Control & Performance

Excessive noise can be a major concern with exhaust fans. Here are key considerations to reduce noise and maintain fan performance:

- Choose Low-Sone Models: Exhaust fan noise is described in sones (1-5 sone level), and a low sone rating indicates a fan with quieter operations. Fans designed with noise-reducing designs/technologies or insulated housings are used as primary fans in residences.

- Proper Mounting: You need to attach the fan securely to the ceiling or wall to avoid vibrations, which are the main source of some additional noises. Try to use mounts or brackets that are specifically designed to reduce the vibrations.

- Use Insulated Ducting: With insulated ducting, the noise generated from the fan and transmitted to other parts of the house is limited. At the same time, insulation helps to prevent any condensation from forming in the ducting, which can be a source of moisture damage.

- Regular Maintenance: By cleaning the fan blades and the ducting regularly, you will be removing dust/debris, which is one of the causes of noise and restricted air flow, and also you will be able to check if the motor bearings are lubricated for correct operation.

Maintenance & Quality Assurance

One of the most important factors affecting the efficient operation of exhaust fans is regular maintenance. The main maintenance processes include:

1. Cleaning the Fan Blades and Housing

Dust and other impurities that stick to the fan blades will cause an imbalance, which can also lead to noise generation. So, the fan blades and the fan case should be cleaned every 3-6 months for ensuring a good performance.

2. Inspecting the Ductwork

The ductwork should always be inspected for adequate airflow to ensure it is not blocked, leaking, or generally damaged. Blockage of ducts may cause decreased airflow and reduce the fan’s ability to discharge air from the room.

3. Lubricating Moving Parts

The motor bearings need to be oiled so that friction between different parts is reduced and the heating or wearing of the lubricated parts does not occur.

4. Checking Electrical Connections

The electrical connections that have wear, corrosion, or are loose need to be inspected. Any loose electrical connection must be tightened, and any damaged wire connectors should be replaced with new ones.

Conclusion

The use of exhaust fans constitutes the very basis of a safe and comfortable environment inside a house or any other building. By knowing their functioning, installation, and maintenance, you can enhance the performance of exhaust fans. Suitable exhaust fans for home or industrial use offer you clean and healthy air, and are also the solution for problems such as mould, humidity, and odors that are generated in your living spaces.