Slabs are an important element of a building, that provides a smooth and horizontal surface. While there are numerous slab options available, what sets the composite slabs apart from the rest of them is their combined effect of concrete and steel, which provides enhanced strength and flexibility with reduced weight. It offers a wide range of advantages, and has become an undeniable option when it comes to choosing the type of slab. This blog takes an in-depth look at composite slabs.

What is a Composite Slab?

A composite slab is a type of floor that uses two or more materials with different physical and chemical properties to remain distinct. Concrete and steel decks are most commonly used for this flooring, where each serves different applications and when combined gives a perfect finished product.

The steel decks act as formwork during construction, providing tensile strength, whereas the concrete layer that covers the steel offers compressive strength. These two materials, when blended, form a strong and stable floor.

Materials Used in Composite Slabs

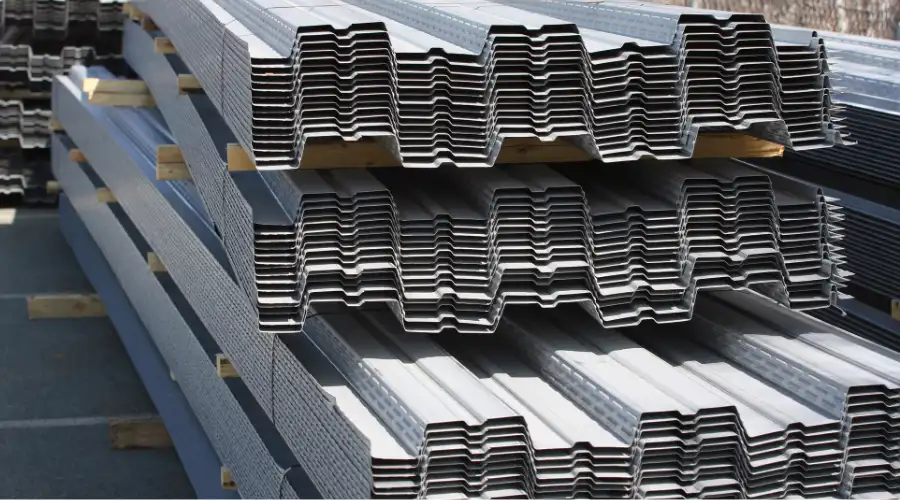

Steel Decking

Steel Decking is a corrugated steel sheet that acts as a base for the composite slab. It is typically made of galvanised steel that protects the structure from corrosion, enhancing the durability of the steel. It acts as a formwork that gives support to the freshly poured concrete. When cured, it supports the structure from compression and tension.

Concrete

It is a mixture of cement, sand, and aggregates that is poured over the steel deck to protect the structure from the external compressive loads. The concrete top-ups when combined with steel decks give enhanced strength and stability to the flooring.

Shear Connectors

These are steel devices in the form of metal studs or pins that are attached to the steel deck to prevent slipping and help transfer shear forces. They are crucial for composite actions between steel and concrete.

Design Considerations

Load Calculations

The slab must be strong enough to support all kinds of loads acting on the surface.

- Dead Loads– This includes the weight of the concrete, steel decks, and other flooring materials.

- Live Loads– These are variable loads that change over time. This includes the weight of the people, furniture, and equipment on the floor.

Span

It is the measurement of how far the slab can stretch between the supports. Longer spans need strong and thick materials. The span should be carefully calculated to resist the tensile forces without failure efficiently.

Composite Action

The composite action between the steel deck and the concrete should be properly maintained using adequate shear connectors. It is essential for effectively transferring the loads between them.

Deflection

The slabs should be designed in a way that does not cause any bending or vibration under excess weight.

How to Install a Composite Slab?

Prepare Steel Decks

Place the steel decks on the beams or the supporting structure and ensure that the ribs are properly aligned parallel to the beams. Use clips or fasteners to secure the steel sheets to the beams and make sure that there are no gaps or misalignments.

Install Reinforcement

Place the steel reinforcement on top of the steel decking. Ensure that they are properly placed, and do not change their position while concrete is poured. The rebars are usually tied together with wire to provide maximum strength and durability.

Concrete Pouring

Pour the prepared concrete into the steel decks, ensuring that it spreads equally and covers the entire surface. Use a vibrator or tamping tool for proper compaction, to remove air pockets, and build a proper connection with the steel decks.

Curing and Strengthening

Allow the concrete to cure for at least 7 to 28 days to achieve the required strength over time. It is necessary to keep the concrete under moisture throughout the curing process to prevent the development of cracks and achieve maximum strength.

Finishing

After curing process, remove the formworks and fix the weak spots. Apply the cement coating over the surface to give a smooth and even finish throughout the surface, making it a usable surface.

Benefits of Composite Slabs

- It is a cost-effective option compared to other concrete slabs, due to its combination of steel deck and concrete layer.

- The design and installation of this slab require less labour force, thereby reducing the cost spent on construction.

- The combined effect of the composite slab provides high strength and durability against compressive and tensile forces.

- As the steel deck acts as a permanent formwork, the need for additional formwork is not necessary, therefore resulting in faster construction.

- These slabs are lightweight, which reduces the overall weight of the building.

- The concrete used in the composite slabs offers high thermal properties, which helps protect the structure from fire and thermal forces.

- It offers great design flexibility in terms of thickness, span length, and load-bearing capacity.

Limitations of Composite Slabs

- Designing composite slabs is complex and requires precise planning and engineering to ensure effective load distribution and performance.

- Poorly installed composite slabs need to compromise performance and have the chance of cracking.

- It provides insufficient sound insulation and requires additional acoustic treatments.

- Although they are resistant to fire, they may not be consistent throughout the surface. This varies based on the thickness.

Conclusion

In summary, composite slabs are highly efficient and versatile options for modern construction that offer a wide range of benefits. These slabs are cost-effective, durable, and have high load-bearing capacity. While it has numerous advantages, there are also certain limitations such as precise design and skilled installation. However, the benefits it offers outweigh the limitations, making it an ideal choice for residential, industrial, and commercial applications.