A wooden finish adds a touch of elegance, tradition, and luxury to buildings and furniture alike. Beyond aesthetics, wooden joints play a crucial role in enhancing both the strength and visual appeal of a structure. While there are many types of wood joints designed for different purposes, they often go unnoticed by most people. In this blog, we’ll explore the various types of wooden joints commonly used in low cost house construction in india and their unique functions.

Different Types of Wood Joints

Butt Joints

A butt joint is a simple and common technique, where two wood pieces are butted against each other edge-to-edge, to provide necessary shape and support. This joint is widely used for decorative purposes, and cannot be used for functional purposes until reinforced.

Miter Joints

It is a type of joint where two wood pieces are cut at a 45-degree angle on the edges and joined to form a corner. These joints are often used in framing or trimming works, to provide a clean and appealing appearance.

Tongue and Groove Joints

It is a combination of two wood pieces, where a tongue fits the matching groove. The joint is easy to fit and guarantees a strong, secure connection. This type of wood joint is widely used in flooring, paneling, and furniture construction.

Half Lap Joints

It is a type of joint, where two pieces of wood are cut halfway through and overlap precisely, providing a strong and flat surface. This material is extensively employed in framing, shelving, and furniture projects

Dowel Joints

In a Dowel joint, both pieces of wood have holes drilled into them, and cylindrical dowels are used to secure them together. It provides a strong, aligned, precise and reliable joint, and is a common choice for furniture, and cabinetry construction.

Coped Joints

It is a type of joint in which the wood is precisely cut using a coping saw to fit seamlessly into the shape of the moulding. This joint is most commonly used in wall moulding or trim works, particularly in corners, where two pieces of wood meet.

Dado Joints

In this type of joint, a groove is made across the grain of one piece of wood trim to create a snug fit with the adjoining piece. The groove cut is wide enough and the joint is reinforced with glue or screws to provide a strong connection. These joints are commonly used in shelving, cabinetry, and creating partitions.

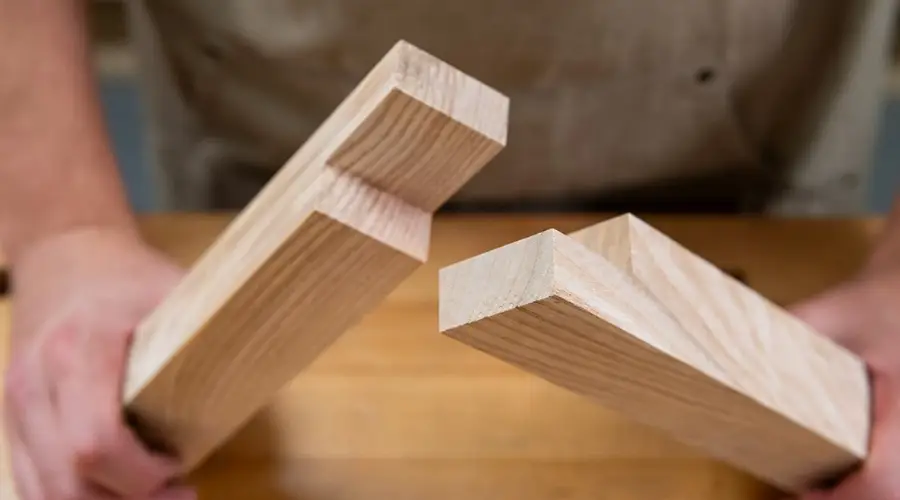

Mortise and Tenon Joints

The mortise and tenon joint is one of the oldest and strongest techniques, featuring a mortise (a hole in one piece of wood) that securely fits with a tenon (a protruding part of another piece), creating a perfect connection. It possesses good strength and is ideal for furniture making, framing and height-strength applications.

Pocket Hole Joints

It is a type of joint where angled holes are drilled into a wooden frame and joined to another piece using screws. The drilled holes are typically invisible, making it an ideal option for decorative furniture construction, cabinetry, and woodworking applications.

Rabbet Joints

A rabbet joint is formed by making a notch along one edge of a wooden piece, into which another piece is fitted. This joint is used for edge-to-edge connections in cabinets, drawers, frames like portal frames and panels.

Biscuit Joints

A biscuit joint is a woodworking technique where thin, oval-shaped wooden discs called biscuits (usually made from compressed beech wood) are inserted into matching slots cut into the edges of two wood pieces using a biscuit joiner. When the glue is applied and the pieces are clamped, the biscuits absorb moisture, swell, and create a tight, aligned, and moderately strong joint. This method is commonly used in cabinetry, furniture making, tabletops, and panel assemblies to ensure precise alignment with minimal visibility, making it ideal for clean, seamless finishes in woodworking projects.

Dovetail Joints

It is one of the most traditional and strong woodworking joints, that features interlocking pins and tails that fit together as a puzzle. The angled cut projection gives a distinctive look and strong interlocking. Providing additional fasteners such as glue, could make it ideal for visual and decorative elements.

Edge Joints

As the name suggests, it is the process of joining two or more wooden pieces along their edges to create a wider and longer surface. The edges of the pieces are usually planed flat to ensure a tight and even fit. It is a versatile and efficient method used for multiple applications such as tabletop, cabinet sides and flooring.

Tambour Joints

Tambour joint involves a series of thin, flexible strips of wood that are attached to the grooves, making it flexible to roll up and down. This joint is commonly used in the construction of cabinets, desks, and other furniture pieces.

Conclusion

Wood joints play an important role in maintaining the functionality, structural integrity, and aesthetics of wood-based constructions. It is used for framing, cabinetry, flooring and other decorative purposes, ensuring good strength, durability, and appealing looks. This blog will help you understand different types of wood joints and could help house owners decide which wood joints can be the best fit for their housing needs.

FAQs

The three primary types of wood used in construction are hardwood, softwood, and engineered wood. Hardwood is obtained from trees like oak, maple, cherry, walnut, and mahogany, while softwood is derived from trees such as pine, spruce, fir, cedar, and redwood. Engineered woods are man-made woods that include plywood, particleboard, MDF, and OSB.

Wood pieces that are joined at a 45-degree angle are called miter joints, which are generally used for decorative purposes such as framing, cabinetry, and trim works.

Although most of the joints are made to provide a balance between strength and looks. Wood joints such as mortise and tenon joints, dovetail joints, biscuit joints, and dowel joints are stronger when compared to other joints.