Today, climate change caused by deforestation is one of the biggest issues plaguing the world. The construction industry is one of the leading contributors to this deforestation, as it uses wood as a crucial building material. However, many new alternatives to solid wood have been developed over the past few decades for use in construction, one of them being blockboards. Continue reading to understand exactly what a blockboard is, its advantages and disadvantages, types, and applications in buildings and learn the blockboard price in India.

What is a Blockboard?

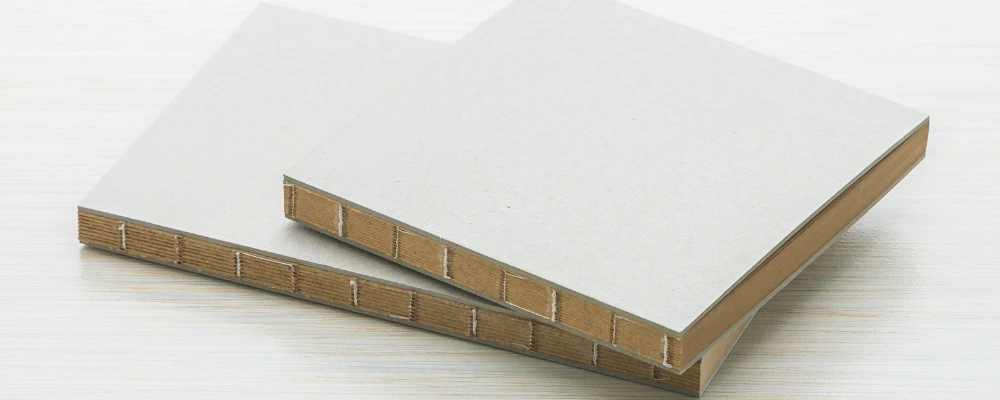

A blockboard is an engineered wood product made by sandwiching softwood blocks or strips between two veneer faces. During manufacture, the softwood strips undergo seasoning to reduce the moisture content. They are then placed edge-to-edge and glued together. Two veneers made of either softwood or hardwood are then placed on the external surfaces and bonded to these under high temperature and pressure to form the final blockboards. These are often referred to as 3-ply blockboards.

Benefits of Using Blockboards in Construction

- Lightweight: A blockboard is much lighter than other engineered wood products like plywood and MDF, thus reducing structural loads when used in buildings. Transportation and labour costs are also significantly lower.

- Ease of Finishing: By using good quality wood veneers on the external faces, blockboards can look like natural wood without any additional finishing. In other cases, these boards have smooth surfaces which can be easily coated with paints, polishes or laminates to obtain seamless finishes.

- Workability: Due to the use of softwood boards or strips in the core, these boards can easily be nailed or screwed and demonstrate good holding capacity for the same. This results in enhanced workability and faster construction with the material.

- Low Cost: With a cost much lower than solid wood and even other engineered wood products like plywood, these boards are affordable materials and ideal for projects with tight budgets.

- Stiffness: These boards are very stiff and can resist bending moments well, even with low weight and thicknesses. Often, these boards can have widths much larger than 5 feet while maintaining high stiffness, which is typically not possible with other engineered wood products like plywood.

Blockboard vs Plywood

Although plywood and blockboard are engineered wood products with similar applications, they both have fundamentally different compositions and properties.

| Plywood | Blockboard | |

| Composition | Made up of thin layers of wood (wood veneers) that are glued together. | Made of strips or blocks of softwood that are glued together and both the external faces have veneers. Often, the edges have an additional banding with veneers to give a clean finish. |

| Weight | Heavier | Lighter than plywood |

| Cost | More expensive | Cheaper |

| Strength and durability | Has higher strength and durability as the wood layers are bonded with no gaps. | Has lower strength and durability as the softwood strips/ blocks can sometimes have gaps between them. |

| Stiffness | Has lower stiffness and its width is generally restricted to a maximum of 5’. | Has very high stiffness and can have widths higher than 5’ without experiencing bending. |

Image source: Link

Types of Blockboard

Types Based on the Wood Used

Although the core is typically made with softwood varieties, the facing veneer sheets can be made with different types of wood, depending on the project requirements.

- Hardwood Blockboard: With veneer faces made of hardwood varieties like teak, rose, oak and maple wood, these boards are much stronger and heavier than softwood types. They are typically used for exterior or decorative purposes.

- Softwood Blockboard: Softwood types like pine, cedar and fir are commonly used to make the facing veneers of these boards. With a lower resistance to moisture, such boards are generally used in interior applications. Pine blockboards are the most common type used in buildings.

Types Based on Special Characteristics

Apart from the standard or commercial grade which is used commonly, blockboards are available with specific properties like:

- Moisture Resistant (MR) Blockboard: Generally referred to as interior grade blockboards, these boards are used for making furniture, storage units and other interior elements. They are made with special moisture resistant adhesives that help resist swelling and warping when exposed to water.

- Boiling Water Resistant (BWR) Blockboard: Also called exterior grade or Boiling WaterProof (BWP) boards, these boards have a high resistance to heat and water. They are used in spaces with high humidity and heat, such as kitchens, bathrooms and railway coaches.

- Marine Blockboard: This is similar to a BWR board, but has much higher resistance to water and can withstand prolonged exposures to it. It is made with very high quality hardwood varieties which are strongly bonded together without any gaps.

- Fire Resistant Blockboard: With the addition of special fire retardant chemicals, these boards can resist fires for much longer than conventional boards. The chemicals form a protective outer layer in case of fires, preventing the interior layers from burning quickly.

- Decorative Blockboard: Such boards have high quality veneer faces that do not require any additional finishing once installed. They are used as a substitute for solid wood and can be left exposed.

Uses of Blockboards in Construction

Blockboards have several important applications in buildings and are used for making:

- Interior Furniture: Elements like sofas, storage cabinets, kitchen units, shelves, chairs and tables are easy to make due to the enhanced workability and stiffness of blockboards.

- Doors: Blockboard doors are lightweight, extremely stiff and affordable, making them a popular choice for spaces that do not experience too much moisture.

- Internal Partitions and Panels: Interior wall cladding panels and partitions made with blockboards can be finished as required- with paints, polishes, laminates or veneers. Thus, such elements offer aesthetic versatility while maintaining stiffness.

Limitations of Blockboards

- Strength: Blockboards have much lower strength and load-bearing capacity than solid wood and other engineered wood products like plywood. Thus they cannot be used for structural or high loading applications.

- Harmful Composition: Formaldehyde resin, which is known to be toxic and cancer-causing, is a chemical that is often used in the manufacturing of these boards, especially when moisture resistance is required. Prolonged exposure to such elements may be harmful.

Blockboard Cost

The blockboard price in India varies depending on several factors like brand, availability, type, adhesive quality, size and thickness. For example, the 25mm block board price will be significantly higher than that of an 18mm board because 25 mm boards are much stronger and stiffer. Blockboards are generally available in standard sizes like 4’ x 8, 7’ x 4’, 7’ x 3’ and 6’ x 4’, with thicknesses varying from 12mm – 35mm and their typical prices are as follows:

| Type of Blockboard | Thickness (mm) | Cost Per Square Foot (₹) |

| Standard Blockboard | 12 – 25 | 15 – 85 |

| MR Blockboard | 18 – 25 | 40 – 100 |

| BWP Blockboard | 18 – 25 | 50 – 120 |

| Marine Blockboard | 18 – 25 | 80 – 250 |

| Decorative Blockboard | 12 – 25 | 60 – 200 |

Supply of Blockboard Ply and Construction Near Me

The quality of blockboards can often be difficult to ascertain as their core materials are either unknown or invisible. However, experts in the construction industry, such as Brick & Bolt, deal with the top brands and manufacturers in India to provide the best building materials supply for their projects. This company also assures premium quality by conducting 470+ quality checks (QASCON) in all its projects, guided by qualified contractors, project managers, site engineers and other construction professionals. To ensure that your building project utilises only the best quality materials like blockboards in construction, reach out to Brick & Bolt today!