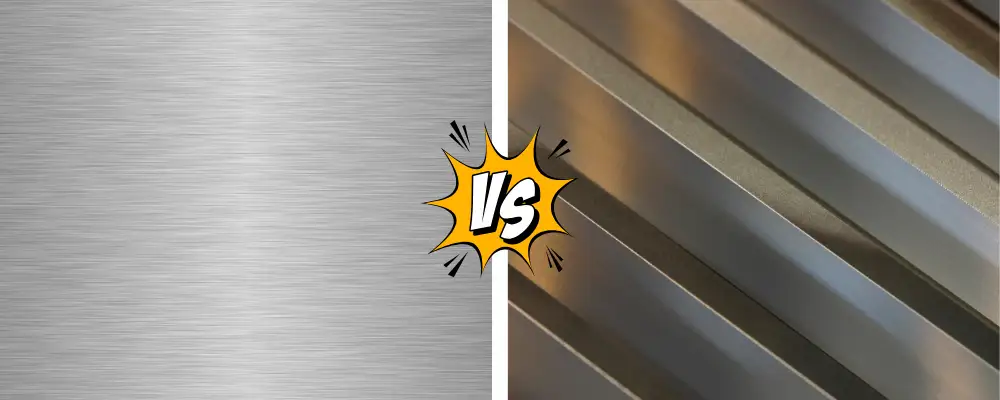

When it comes to steel applications in construction, roofing, and fabrication, two popular choices often come into play – bare steel and corrugated steel. While both are strong, durable, and versatile, they differ in appearance, performance, maintenance needs, and ideal use cases. Understanding these differences is essential for making the right choice, whether you’re building a structure, installing a roof, or working on a custom metal project. In this blog, we’ll compare bare steel and corrugated steel in detail, exploring the properties of steel, pros and cons, and where each material works best.

What is Bare Steel?

Bare steel is steel in its natural state without any form of coating or treatment, such as painting or galvanization. Carbon mild steel is generally adopted as its main component, which, while it has high tensile strength it is rather poor in corrosion resistance due to the lack of alloying elements like Chromium or Zinc.

Therefore, low carbon steel, which is a non-protected one, is prone to rust when it comes in contact with water and air. It is still, however, widely used in the construction sector for parts that will be treated or where a short time of exposure is allowed. Its less expensive nature makes it possible for it to be the favourite in many areas of industry.

What is Corrugated Steel?

Corrugated steel is a versatile sheet material characterized by its distinctive ridged or wavy pattern, which significantly enhances its strength and rigidity while keeping it relatively lightweight for its strength class.

Typically, the material is made of cold-rolled steel, and the corrugation technique enhances the steel’s load-bearing capacity and impact resistance, making it suitable for applications in construction, such as roofing, siding, and cladding. Sometimes a protective coating, such as zinc (galvanization) or paint, is applied to the corrugated steel, from which it highly durable and resistant to corrosion.

Key Differences Between Bare Steel and Corrugated Steel

Both bare steel and corrugated steel are essential in construction; however, they differ significantly in their respective functions due to their distinct features.

1. Material Structure and Strength

- Bare Steel: Essentially, bare steel is in the form of a flat or coil, and thus, it gives more versatility to the fabrication process. Mostly, it is recommended to use bare steel for its tensile strength; however, in the case of the structural reinforcement needed for applications with high rigidity requirements, it will not suffice. Without additional support, it can be easily deformed or even dented by the application of force.

- Corrugated Steel: The ribbed design of corrugated steel leads to increased rigidity and greater load capacity. The stress is spread out evenly over the material from the corrugated shape, and thus it can resist bending and deformation under pressure. This structural advantage makes corrugated steel an ideal choice for applications such as roofing and siding, where maintaining structural integrity over time is critical.

2. Corrosion Resistance

- Bare Steel: Without a protective layer, steel is highly inclined to corrosion when in contact with water, chemicals, or severe weather conditions. Rusting takes place very quickly; thus, the life of the steel and its structural properties are also decreased. It requires maintenance and protective treatments, such as galvanization, for outdoor purposes.

- Corrugated Steel: Most of the time, corrugated steel is pre-treated with protective coatings like galvanization, zinc-aluminum alloys, or paint. This gives the steel the features of good resistance against rust and corrosion. Besides, the ribbed design also allows water to drain efficiently, which, in turn, reduces the possibility of moisture accumulation and therefore increases the durability of the material in outdoor applications.

When to Use Bare Steel?

- Internal Structural Components: Bare metal is good for the main support structures of buildings, like beams, columns, and frames, in dry, closed spaces where rust is not an issue.

- Cost-Effective Short-Term Applications: Bare steel is the best choice for temporary works such as scaffolding or formwork that are not required to be protected for a short period of time.

- Pre-Coating Applications: It is a through-product in nature before the metal is galvanized, painted, or any other protective layer is applied.

- Welding and Fabrication: It can be used for custom fabrication and welding, as the original surface facilitates bonding and adhesion of the materials.

- Low-Exposure Environments: It can be used in dry areas with low humidity where the risk of corrosion is minimal.

- Non-Exposed Machinery Parts: Parts inside machines made of internally protected materials from decomposition due to ageing and weathering are made using bare metal.

When to Use Corrugated Steel?

- Roofing in Harsh Climates: A material that is water-resistant and can hold its shape under pressure is thus a metal that is best for areas with heavy rain, snow, or strong winds.

- Commercial & Industrial Buildings: This metal is ideal for large-scale warehouses and factories, offering durability with a low weight-to-strength ratio, which reduces the structural load required.

- Agricultural Structures: their use in barns, sheds, and silos is just perfect. Its resistance to rust and weathering, especially when galvanized, makes it the most compatible outdoor agricultural product.

- Affordable Cladding & Siding: This metal is a very cheap option for siding and cladding, practically a cost-effective one with its long-term performance without any significant maintenance.

- Fencing: It is a metal that can commonly be seen in the formations of secure fences due to its impact resistance and long lifespan in industrial and high-security areas.

- Environmental Durability: The said metal is the best option for coastal or extreme temperature areas, where other materials may degrade more quickly in the degradation process

Which is Better: Bare Steel or Corrugated Steel?

The decision of whether to use bare steel or corrugated steel hinges largely depends on the kind of work you want to do.

- Where strength and durability are the main things to be considered in the case of a very tough environment, particularly in roofing or structural uses, then corrugated steel is the best choice. Its ridged shape gives the structure more strength under loading as well as being more resistant to environmental stresses, especially when the iron product is galvanized or treated for rust resistance.

- If your work is cheaper and lighter, then bare steel will be the best option, especially when the protection of metals from oxidation can be easily done by painting or coating. The product is also suitable for the use of elements in non-structural applications or exposure-free situations.

The decision you make should be informed by three key parameters: the environmental condition, structural requirements, and the project’s aesthetic appeal, all of which are crucial in selecting the right steel type.

Conclusion

Both bare steel and corrugated steel play important roles in construction, each offering distinct advantages. Bare steel is cost-effective and strong, but it lacks the protective coatings or structural enhancements that corrugated steel provides. Corrugated steel, on the other hand, offers superior weather resistance and long-term durability, making it ideal for external applications such as roofing and siding.

Ultimately, the choice between the two depends on the project’s specific requirements; factors like budget, expected lifespan, and exposure to environmental conditions will guide the selection to ensure the best performance and value.