Conduit wiring is an integral part of any kind of modern construction or electrical system. It is executed with the help of a method that is organised and safe for varying types of cables. For ensuring safety, durability, and compliance with electrical codes in different kinds of buildings, one must get to know about their types, components, and installation processes. So keep reading!

What is Electrical Conduit Wiring?

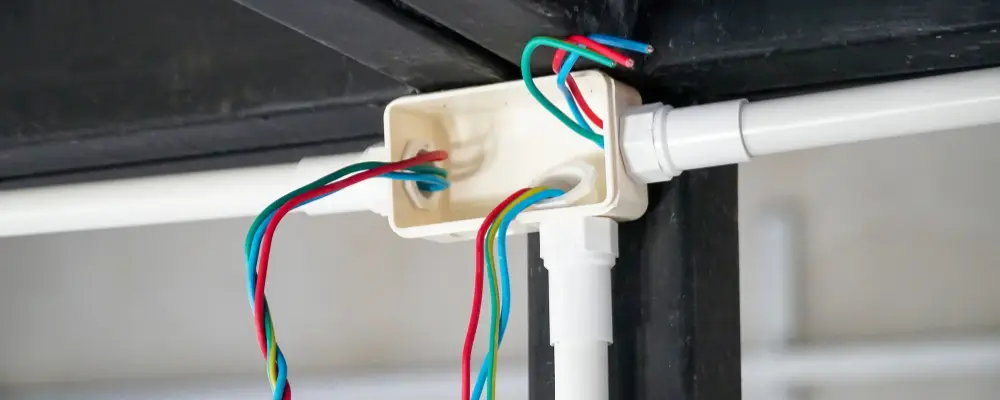

Electrical conduit wiring basically means to wrap or cover all the wires and cables in a protective tubing or pipe system that will keep them safe from external damage and still allow a smooth flow of current to different parts of a building. The conduit is a shield against the elements for wiring, giving them extra protection as well as systematically streamlining the flow of electricity. One of the main things that conduit wiring does is safe wiring to keep the electrical cables safe from any kind of damage (which could be done by water, chemicals, or other things).

Core Components of Conduit Wiring

Some of the most important components of conduit wiring are,

- Conduit Tubing: This is the main part of the whole system that deals with the protection of cables from the external environment. It consists of pipes through which electrical cables and wires are routed.

- Connectors: These are the pieces that physically unite the different parts (or sections) of the conduit, so that the wiring can be easily transported through a single network of conduits.

- Electrical Wires: The inner part of the wire, made up of non-metallic and metallic materials, which is connected to the wire holder, and through which electricity is carried to the end user.

- Conduit Couplings: Function as the connectors of joints between two conduit sections, thus establishing a connection that is not only safe but also continuous.

- Conduit Straps: Firstly, these straps, made out of steel, plastic, or other durable materials, are the means through which conduits are fastened to walls, ceilings or other surfaces. Secondly, they not only allow for the proper installation of the aligned system but also secure the system from displacement.

- Conduit Bushings: These are the safety devices installed at the wire entrance or wire exit points of the conduit. Their role is to prevent the wires from abrasion against the sharp edges of the conduit and thus to increase safety.

- Conduit Elbows: These are the elements that allow conduits to work around corners and bends easily and are essential for a continuous wiring flow without any stress on the cables.

- Conduit Locknuts and Washers: In short, they are the means through which the safest possible way of mounting the conduits to the boxes is achieved, while preventing loosening and giving a tight, stable connection.

- Conduit Caps: They close the open ends of conduits, and hence the wiring is protected from dust, moisture, as well as other impurities.

- Conduit Hubs: Are the designated points of structured entry or exit for conduits in enclosures or boxes.

- Grounding Bushings: They are devices meant to ensure the proper grounding of metallic conduit systems so that they can be safe and not cause any electrical hazards.

- Conduit Adapters: Allow a change of one conduit size or type to another without affecting the strength or tightness.

Importance and Advantages Over Other Wiring Systems

There are many benefits of conduit wiring over traditional open or surface-mounted wiring systems, including:

- Enhanced Protection: Enclosures give maximum protection against all kinds of damage to the wires, thereby maintaining the wires’ wellness.

- Meet Safety Requirements: Conduit systems are usually able to satisfy the regulations required in national and local building codes, for example, in the case of commercial and industrial buildings.

- Aesthetic Appeal: Hidden conduit wiring tends to look neat and clean because wires are run inside walls, which greatly reduces or nullifies the number of wires that are in sight, thus reducing visual clutter.

Types of Conduit Wiring

1. Surface Conduit Wiring

Conduits are placed along the surface of walls, ceilings, and floors in this type. It is generally used in a place where a quick and easy installation is the main priority, for example, in an industrial setting or a retrofit project. This method is both cost-effective and time-efficient, which is great for temporary installations or areas that are constantly in need of an update to the electrical system. However, it is less aesthetically pleasing as the conduits are clearly visible.

2. Concealed Conduit Wiring

This involves the conduits being installed inside walls, ceilings, or floors, thus giving a neat and orderly look. Generally, it is recommended for homes that have already been constructed in a modern style, especially for residential and commercial properties. As well as preventing physical damage, concealed wiring ensures that electrical services and wiring mechanisms are hidden from view. It involves accurate drafting and routing across walls, ceilings, and other surfaces, which thereby makes the installation longer.

Classification of Conduits (as Per IS Code)

According to the Indian Standards Code IS 9537-1 (1980): Specification for conduits for electrical installations, conduits can be classified based on the following aspects:

a) By Material

- Metal conduits

- Insulating conduits

- Composite conduits

b) By Connection Method

- Threadable (applicable to plain conduits only)

- Non-threadable: plain or corrugated

c) By Mechanical Strength

- Conduits for very light mechanical stresses

- Conduits for light mechanical stresses

- Conduits for medium mechanical stresses

- Conduits for heavy mechanical stresses

- Conduits for very heavy mechanical stresses

Conduits which are designed for higher mechanical stresses can also be used for lower mechanical stresses.

d) By Flexibility

- Rigid conduits

- Flexible conduits

- Self-recovering conduits

- Pliable conduits

e) By Flame Resistance

- Non-flame propagating

- Flame propagating

f) By Electrical Properties

- With or without electrical insulation

g) By Resistance to External Conditions

- Resistance against water ingress: unprotected, splash-proof, wave-resistant, or immersion-resistant

- Resistance against corrosion: low, medium, high; inside/outside protection variations

- Resistance against solar radiation: Unprotected, low, medium, or high solar protection

Conduit Materials and Their Uses

Metal Conduits

EMT (Electrical Metallic Tubing)

It is a rigid steel tube with thin walls and low weight made of galvanised steel, which can be used in the house and the office. Simple to work and fit, it offers a modest level of defense from injuries. It is often used for internal wiring in dry conditions, as it does not offer great resistance to moisture.

IMC (Intermediate Metal Conduit)

It is a heavy-duty steel pipe that gives the utmost protection to the wire against any kind of physical harm. Compared to EMT, it is more solid and less susceptible to wear from impacts and fire safety. It can be used in particular factories and business places where protection from physical stress is required.

Flexible Metal Conduit (FMC) & Liquid-Tight Flexible Metal Conduit (LFMC)

FMC has a helical metal design, which allows it to be easily bent for use in walls or other installations. Typically, it is used for short, outdoor runs that are exposed, such as the installation of wires on water heaters or garbage disposers. LFMC is a plastic-coated FMC that makes the conduit completely watertight and is suitable for applications such as air conditioning units or external equipment in outdoor areas.

Rigid Metal Conduit (RMC)

RMC is a galvanized steel heavy-duty metal conduit for structural wiring that connects buildings to utility lines. It is equipped with threaded joints for assembly purposes.

Non-Metallic Conduits

PVC (Polyvinyl Chloride)

It is a type of plastic mostly used in homes, offices, and outdoors, and is a good choice for non-metallic systems. It is non-corrosive, lightweight, flexible, and resistant to chemicals and environmental damage. It is a product that comes highly recommended in wet spaces, or where the wiring is underground, and the outdoors. It is relatively cheaper and easily available.

HDPE (High-Density Polyethylene)

It is a versatile and lasting conduit that is used in the ground and extreme conditions. It is resistant to chemicals, such that it will not suffer. Perfect for being buried directly in difficult environments, such as storm drains and industrial areas.

Non-Metallic Liquid-Tight Flexible Conduit (NLT)

It is made of flexible PVC and used as a substitute for LFMC in the case of lower cost requirements. Typically, it is used for indoor applications where a watertight seal is essential, and the installation is carried out using the connectors provided.

Pros and Cons of Conduit Wiring

Advantages

- Safety: Conduit wiring ensures that safety measures are in place to protect wires against physical damage. Consequently, the risks of fire and electrocution are minimised.

- Protection: Wire insulation alone cannot resist water, acids, and low or high temperatures, especially if the wires are used outdoors. A conduit will be a perfect solution in this case.

- Aesthetics: The hidden conduit delivers a neat and aesthetically pleasing installation which does not showcase wires and other utilities.

- Improved Durability: Hidden conduits protect the wiring against water, dirt, and insects; thus, the system keeps working for a longer period of time, and the need for maintenance decreases.

- Minimised Interference: The protected electrical wires are isolated from the electromagnetic and radio frequency interference, thus an uninterrupted performance of the sensitive devices can be achieved.

- Flexible Outlet Placement: Covered wiring enables more flexibility in the location of outlets, switches, and fixtures, and thus further changes in the electrical system will be simpler to carry out.

Disadvantages

- Cost: Conduit systems cost more than traditional exposed wiring, not only in terms of the materials but also in the labour costs.

- Installation Time: Due to the steps of planning, bending, and securing the conduit, the installation is a longer process.

- Complexity: It is a very complicated job that requires careful preparation, knowledge of the types of bends and fittings, and professional intervention for the proper installation.

Key Installation Considerations

1. Planning the Layout

- Assess the Building Design: The process should start with understanding the electrical needs of the building. By thinking of where the appliances, lights, sockets, and panels will be, you can come up with the most optimal conduit routing.

- Map Out Conduit Pathways: Establish the shortest and cleanest routes to the conduit without the help of any other accessory. Try to keep the bends as few as possible and avoid going through the places that are more likely to get damaged or are structural components of the building (i.e., beams, columns, etc.).

- Check Building Codes: Confirm if the electrical layout is fulfilling the local building codes and regulations. Think about the changes or the growth that will happen shortly to make sure that the conduit system can still be used.

2. Bending the Conduit

- Choose the Right Bender: In order to select the bender type(manual or power), determine the type of conduit material (PVC, EMT, IMC, etc.) which should be used.

- Follow Bend Radius Requirements: Use the bend radius as suggested for the specific material, providing a kink-free and wire-friendly bend. Different Indian standards specify the guidelines for the wire bend radius depending on the conduit type and material.

- Measure and Mark Bends: The accurate measurement and marking of the bending spot on the conduit are the keys to ensuring the exact angle and smooth electrical flow.

3. Fitting the Conduit

- Use Proper Fittings: Simply put, you can use the relevant fittings (elbows, couplings, connectors) to change the direction, make a transition, or join the separate lengths of the conduit.

- Secure Conduit Properly: Make sure that all the conduit joints are securely fastened and sealed to prevent loosening over time. Use compatible fittings to maintain the structural integrity of the conduit.

4. Wire Pulling

- Select the Proper Wire Size: The first step you should take is to choose the suitable cables for the given electrical load. Also, it is important that you ensure the wire is neither too tight nor too loose in the conduit.

- Put on Some Lubricant: A wire-pulling lubricant is used during the wire-pulling process to minimise the friction that occurs. Thus, the wires will be less exposed to the risk of damage, and the process will be more efficient.

- Unhook the Wire Hand Carefully: Slowly and evenly, pull the wire, making sure it goes through the conduit without any jerks or abrupt movements, which may cause the wire to be damaged.

Conclusion

Conduit wiring represents one of the fundamental elements of the electrical installations in contemporary buildings, through which the user is granted not only functionality but also safety. Whether you are using metal or non-metallic conduits, surface or concealed wiring, it is absolutely necessary to grasp the kinds, benefits, and even the installation aspects of the conduit systems. As a result of correct planning with wiring diagram and installation, conduit wiring can provide the users with safety, functionality, and decorative value for their houses, offices, factories, or any other built structures.