Clamps serve as reliable tools in diverse fields such as building, fabrication, and home improvement. Clamps are mechanical devices that hold workpieces in place with controlled pressure, safeguarding them against movement during the crucial operation. Clamps are trusted by engineers and workers for accuracy, security, and effectiveness in operations. The choice of the right clamps has a direct effect on the quality of projects and workplace efficiency.

Advanced materials and ergonomic designs characterize modern clamps to address various application demands. This extensive guide discusses different clamp categories, technical specifications, and real-world applications in modern construction and manufacturing settings.

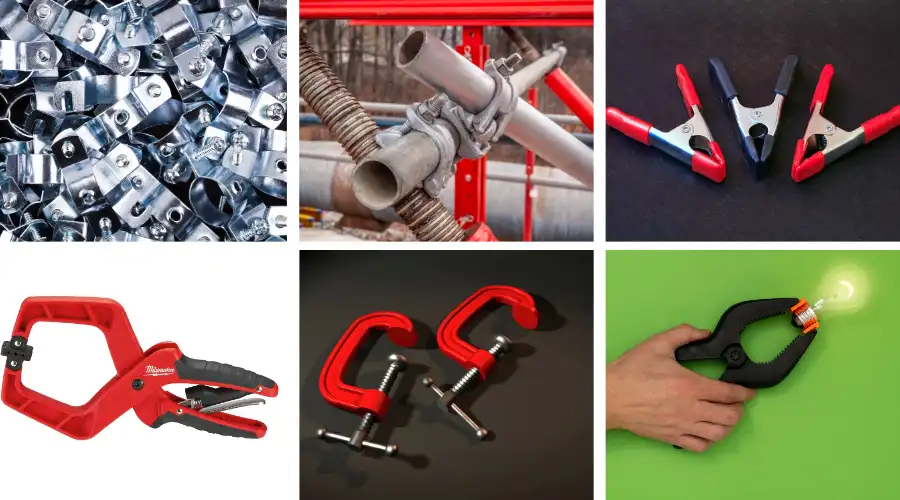

Types of Clamps Used in Construction

1. General-Purpose Clamps

- C-Clamp

C-clamps take their name from their characteristic C-shaped frame that offers access from several directions. C-clamps are versatile clamps made of a fixed anvil, a threaded screw, and a sliding jaw for applying pressure.

- F-Clamp

F-clamps have an F-shaped profile with a long bar and a perpendicular fixed jaw that offers good reach and versatility. The sliding head traverses along the bar and gets secured in place.

- Bench Clamps

Bench clamps fasten to workbenches and offer rigid clamping platforms for a number of operations. Bench clamps have fixed bases that bolt onto bench surfaces and sliding jaws that are adjusted to hold workpieces.

- Hand Clamp

Hand clamps function by applying manual force and have lever or spring-loaded mechanisms for rapid operation. Hand clamps are portable and have one-handed operation to ensure ease of use in temporary holding operations and positioning.

- Quick Action Clamps

Rapid-action clamps have quick adjustment and positioning via trigger devices that enable one-handed use. These clamps have sliding jaws on cam-lever locked guide bars.

- Spring Clamps

Spring clamps employ spring tension to apply continuous clamping pressure through simple, high-reliability mechanisms that don’t need adjusting. These clamps have pivoting jaws linked by spring mechanisms that automatically keep pressure on.

- Table Clamps

Mounted on work surfaces, they use the table’s weight to keep materials stable during jobs. These clamps have mounting systems that are attached to the edges of tables.

2. Heavy-Duty & Structural Clamps

- Beam Clamps

Beam clamps mount on structural steel beams and offer stable lifting points for heavy material. Beam clamps have heavy-duty construction with hardened steel jaws that efficiently grip I-beams, H-beams, and other structural members.

- Pipe Clamps

Pipe clamps utilize a common plumbing pipe as the clamping bar, providing nearly unlimited length capacity for huge workpieces. Pipe clamps are made up of pipe heads that are mounted firmly upon threaded pipe sections.

- Dimide Clamp

Dimide clamps are heavy-duty options for common C-clamps with increased torque capacity and longevity. Reinforced and rigid frame structure and strong screws apply heavy pressure, making them suitable for tough industrial work.

- Sash Clamps

Sash clamps have extended rigid bars compared to pipe clamps, but with internal jaw systems built with woodworking applications in mind. These clamps are ideal for large panels due to their extended reach and high holding capacity.

- Scissor Clamps

Scissor clamps employ pivoting jaw mechanisms that increase applied force through mechanical leverage, much like scissors or pliers. Scissor clamps have crossing arms that multiply the force applied at the handles.

- Material Handling Clamps

Used in industries, they help move and position heavy materials safely and efficiently. Material handling clamps have strong construction capable of tolerating dynamic loading during transportation and lifting operations for safety reasons.

- Vertical Plate Lifting Clamps

Vertical plate lifting clamps hold steel sheets and plates to vertically lift and position them in manufacturing settings. They have cam devices that grip plate edges and hold them tightly.

3. Precision & Specialty Clamps

- Miter Clamps

Miter clamps are designed to hold workpieces at specific angles, commonly 45 degrees for corner joints in mouldings and frames. Miter clamps have slanted surfaces that are able to maintain correct joint geometry when assembling.

- Picture Frame Clamps

Picture frame clamps offer simultaneous pressure on all corners of rectangular picture frames throughout assembly and glueing processes. Picture frame clamps employ cord systems that go around the perimeter of the frame to distribute pressure evenly.

- Cabinetry Clamps

Cabinet clamps are experts at gripping cabinet face frames and panels for assembly operations. Wide, padded jaws press evenly on wood surfaces, holding them tightly without leaving scratches or damage.

- Edge Clamps

These tools grip from both the side and top, stopping the material from shifting in any direction. The clamps have three individual adjustment screws that permit precise positioning of the clamping elements to ensure precision.

- Web Clamps

Web clamps make use of flexible webbing or straps to hold irregularly shaped items or a variety of workpieces that cannot be restrained by standard rigid clamps. They have ratcheting devices to provide tension.

- Wood Hand Screw Clamps

Wood hand screw clamps incorporate traditional wooden jaw build with double-threaded screw mechanisms that grant independent jaw adjustment and skewed clamping. These clamps offer superior workpiece protection via wooden surfaces.

- Kant-Twist Clamp

Kant-twist clamps have a specially designed jaw geometry that evenly distributes the clamping loads and resists twisting forces when tightening. Kant-twist clamps utilize cam mechanisms that offer fast clamping action with little handle rotation needed.

4. Mechanically Powered Clamps

- Mechanical Clamps

Mechanical clamps work through mechanical advantage mechanisms with levers, cams, or screw mechanisms without any external power source. Toggle handles, arms, and linkages work together to create firm and steady pressure for secure holding.

- Hose Clamps

Hose clamps hold soft hoses to hard fittings and ensure fluid system leak prevention. Hose clamps consist of circular rings with adjustment devices that constrict around hose surfaces for leak-free joints.

- Locking Chain Clamps

Locking chain clamps employ flexible chains to clamp irregularly shaped items or several workpieces at a time. Locking chain clamps have locking devices that hold the chain and apply tension without slippage or relocation.

- Sheet Metal Clamps

Sheet metal clamps have broad, flat jaws specially designed to grip thin material without deforming or marking. Sheet metal clamps apply clamping pressure to large areas in order to avoid marking.

5. Powered Clamps

- Pneumatic Power Clamps

Air-powered systems apply fast and repeatable pressure, ideal for tasks that need quick clamping. Pneumatic power clamps have air cylinders that translate pneumatic pressure into mechanical pressure.

- Hydraulic Clamps

Hydraulic clamps utilize pressurized fluid to provide extremely large clamping forces with little operator force. Hydraulic clamps have hydraulic cylinders that amplify input force with fluid pressure, applying measured clamping forces.

5. Electrical/Earthing Clamps

- Ground Clamp

Ground clamps make electrical connections between grounding electrodes and conductors for protective purposes and equipment safeguarding. Ground clamps have copper or bronze construction with good corrosion resistance and low electrical resistance for protective purposes.

Common Uses of Clamps According to Their Types

| Clamp Type | Common Uses |

| Beam Clamps | Suspending loads from structural beams |

| Bench Clamps | Holding materials steady on workbenches |

| C-Clamp | Woodworking, metalworking, and general-purpose clamping |

| Cabinetry Clamps | Assembling and aligning cabinets |

| Dimide Clamp | Heavy-duty applications requiring high force |

| Edge Clamps | Securing edges during glueing or joining |

| F-Clamp | Clamping large or wide workpieces |

| Ground Clamp | Creating secure ground connections in electrical work |

| Hand Clamp | Quick, temporary holds in various tasks |

| Hose Clamps | Securing hoses in plumbing and automotive systems |

| Hydraulic Clamps | High-precision clamping in manufacturing |

| Kant-Twist Clamp | Applying even pressure without twisting |

| Locking Chain Clamps | Securing irregularly shaped objects |

| Material Handling Clamp | Lifting and moving heavy materials |

| Mechanical Clamp | Versatile clamping using mechanical advantage |

| Miter Clamps | Holding miter joints at precise angles |

| Picture Frame Clamps | Assembling picture frames with tight joints |

| Pipe Clamp | Adjustable clamping for large woodworking projects |

| Pneumatic Power Clamps | Quick, repetitive clamping in automated systems |

| Quick Action Clamps | Rapid clamping and release for efficiency |

| Sash Clamps | Clamping large assemblies like doors or windows |

| Scissor Clamps | Lifting applications require a strong grip |

| Sheet Metal Clamps | Holding thin metal sheets without damage |

| Spring Clamps | Quick and light clamping tasks |

| Table Clamps | Securing objects to tables or workbenches |

| Vertical Plate Lifting Clamp | Lifting and moving metal plates vertically |

| Web Clamps | Applying even pressure around irregular shapes |

| Wood Hand Screw Clamps | Precise control in woodworking tasks |

Conclusion

The wide variety of clamps used nowadays is a testament to the advancement of manufacturing and construction types and methods over several decades. Each category of clamp is designed for specialized purposes that meet specific demands in contemporary fabrication and assembly work. Our knowledgeable crew is aware of the crucial role of adequate tools and methods in achieving outstanding results. Call Brick & Bolt now to revolutionize your building projects with expert service and unwavering performance that surpasses expectations.