Gauges are used in engineering and manufacturing for measuring specific parts. With a gauge, you can check if a part of a component is fit for use and, and offer additional measurements. Because of this, there will be no waste of resources. Measuring the quality of parts and components, along with their variability, becomes simple and efficient.

Gauges are easier to operate than callipers and micrometre measuring devices when it comes to repetitive checks. The assignments fall within certain bounds, which are determined. Selection of the proper gauge is one of the most important, enabling the outcome of the measurement to be exact and trustworthy.

Gauges serve to control the uniformity of the production and the precision of the measurements. The use of the gauges facilitates minimum error occurrence and minimum probability of faulty parts being produced. An individual who is engaged in manufacturing or in charge of quality control must know the types of gauges and their functions.

To meet the gaps in measuring, several types of gauges are made. A non-ferrous example of this is the American Wire Gauge.

Overview of Gauges

Gadgets have their uses in engineering and manufacturing. They help verify that the parts being worked on meet certain measurements. Unlike measuring devices that give a quantifiable value, gauges offer a simple go/no-go indication. This makes them convenient, especially in production settings where high output and uniformity are essential.

Gauges aim to check whether the dimension of a given part conforms to specified tolerances. A gauge is mostly used to track whether a part is within a certain range of limits rather than detailing an accurate number.

Some of the things that make gauges extremely helpful include:

- Speed: Gauges enable quick estimation of part measurement.

- Simplicity: A minimal amount of training is needed to use them.

- Consistency: Reduces the chances associated with manual measurements.

Gauges assist in maintaining quality standards because, with the use of gauges, it is easy to check whether the parts produced are interchangeable and if they conform to the required standards. Because of their straightforward methods and speed, many industries heavily rely on them.

Types of Gauges

The following are the different types of gauges.

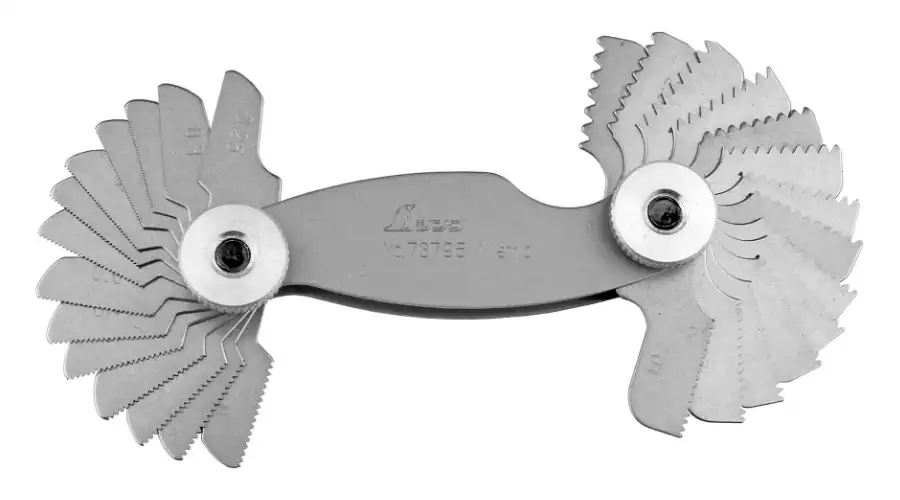

Thread Gauge

Screw threads are checked for their proper alignment with the help of a thread gauge and its array of plugs, anchor bolt and ring gauges that are designed for internal and external threads respectively. These gauges ensure that threads are within the specified tolerance for proper fit and function.

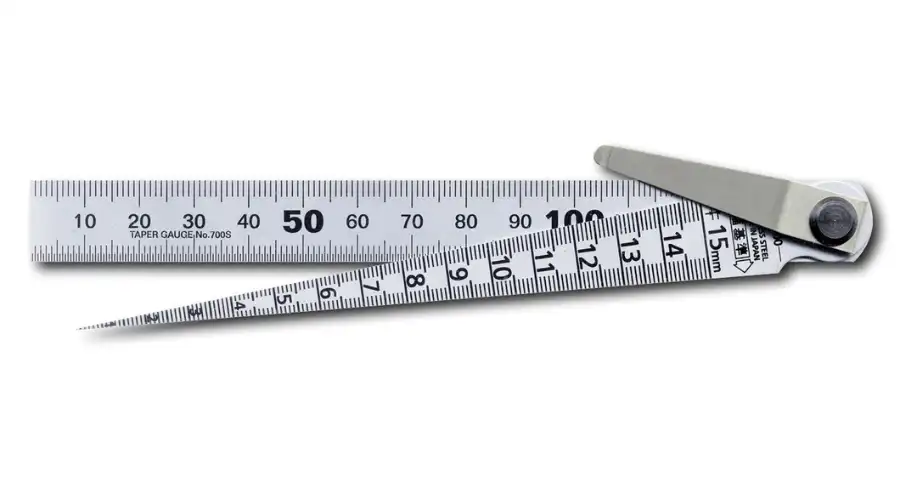

Taper Gauge

For any taper or conicity angle of a part, taper gauges are used. They come in handy when precision instruments require a certain angle of attachment like inside the spindles of machine tools and valves. For instance, a correctly fitting taper plug gauge has to be within certain limits in order for it to fit.

Snap Gauge

Snap gauges are employed for checking external dimensions rapidly. They have a set gap or aperture that marks the allowable tolerance limits. The part must pass through the \”go\” side of the gauge but not the \”no-go\” side to ensure that it is within the required limits. There exist different types of snap gauges, such as:

- Double ended

- Progressive

- Adjustable

Ring gauge

Cylindrical parts’ accuracies can be checked using ring gauges which check external diameters. Like snap gauges, they are also ‘go’ and ‘no-go.’ While maintaining the set part ring slides over it, the no-go set does not.

Plug Gauge

Screwholes and holes can be measured with plug gauges, which test the internal diameters with a ‘go’ and ‘no-go’ end. One side of the cylinder is the ‘go,’ which has to be accepted in the hole and the no-go which should not enter for set tolerances. Plug gauges can be:

- Double-ended

- Progressive

- Hardened steel Plug gauges with gauging surfaces

Form Gauge

Form or profile gauges are instruments which check the shape or contour of a part. The part to be inspected is custom made to the specified profile. A comparison to visually check whether the part is within required form is done using these comparators. This is especially helpful for measuring very complex shapes which cannot be captured through dimensional measurement.

Feeler Gauge

A feeler gauge is made up of thin metallic blades of varying thickness. An appropriate amount of blades is used to measure the gap between two surfaces. In mechanical engineering, feeler gauges are widely used in automobiles to adjust the clearance between valves or the gaps in spark plugs. The operator places blades with increasing thickness sequentially until they reach a gap where the thickness does not exceed, marking the gap measurement.

Common Uses of Gauges According to Their Type

Gauges are not merely tools that can be found lying around without purpose; they are designed for highly specific applications. The following table indicates the uses of gauges according to their types.

| Type of Gauge | Purpose | Common Uses |

| Thread Gauge | Measures thread pitch, form, and diameter. | Automotive assembly, mechanical design, screw fitting. |

| Taper Gauge | Measures conicity angles and taper diameters. | Machine tool spindles, valve fittings, and tapered drill bits. |

| Snap Gauge | Provides quick checks of external dimensions. | Shaft diameters, part widths, and material thickness. |

| Ring Gauge | Measures internal diameters of cylindrical parts. | Hole diameters, cylindrical part sizing, and ensuring parts fit. |

| Plug Gauge | Measures internal diameters and hole shapes. | Hole diameters, depth, and straightness in manufacturing. |

| Form Gauge | Measures part geometry and profile. | Complex curves, ensuring proper geometry in precision parts. |

| Feeler Gauge | Measures the gaps between two surfaces. | Valve clearances, electrical contacts, and machine components. |

Now, let’s explore in detail:

Thread gauge

Thread gauge are largely concerned with the precise measuring of threads on screws, bolts, and nuts. With a thread gauge at hand, no one will end up with a loose threaded screw.

Determine:

- Thread spacing (pitch measuring)

- Form (the shape of the thread)

- Diameter (size of the base of the thread)

In essence, thread gauge becomes useful for any assembly which entails screwing.

Taper gauge

Measuring the rate at which things narrow towards an end is the job description of taper gauges. Tapers can be anything from cones to most of straight edged objects.

For example: Taper gauge are used for measuring:

- Measuring taper angles

- Measuring taper diameters at particular locations

- Measuring the overall uniformity of a taper

Snap gauge

A snap gauge serves as a rapid assessment tool that validates proper calibration against a set standard. It’s used for:

- Shaft diameters

- Widths of parts

- Thicknesses of materials

These too are known as:

- External Snap Gauges

- Simple Snap Gauges

- Mechanical Snap Gauges

Ring gauge

It is the opposite of Snap Gauges, as it checks internal diameters as well. They’re used for:

- Hole diameters

- Size of the cylindrical part

- Ensuring parts fit together properly

Plug gauge

Similar to the plug gauge, these check the size and straightness of holes. They’re used for:

- Check hole diameters

- check depth of the hole

- ascertain if the hole is cylindrical or tapered

Form gauge

These are the artists of the geometry gauges. They’re used for:

- Checking complex curves

- Ensuring that the parts have the right geometry

- Master profile design

Feeler gauge

Unlike form gauges, these are all about minimal gaps or separations. They’re used for:

- Setting valve clearances within engines

- Checking the gap across electrical contacts

- Measuring spaces between machine components.

Gauges are indispensable for maintaining quality standards in the manufacturing process. They assist in checking that parts are produced to the correct size and that they interrelate appropriately. The proper gauge for the task saves both time and money by preventing mistakes and minimizing waste.

Conclusion

As you can see, we have reviewed several types of gauges and their common applications. It is easy to appreciate their value across many industries. From ensuring that threads are correctly placed to measuring the thickness of sheet metal, gauges are certainly critical to achieving precision.

Selecting the right gauge for the task is of utmost importance. The wrong one can produce inaccurate measurements which will waste materials and pose a safety hazard. It is essential to learn about the various types and how they are used in different cases.

Consider this; we would still be in the ages of trial and error if it were not for these tools. Trying to accurately measure the components of a car or a plane would create unimaginable havoc. Gauges have made, and continue to make, both engineering and manufacturing far more accurate. They ensure proper fitting and standards compliance which, for accurate measurements of structural steel fabrications, is critical.

Here’s a quick recap of their importance:

- Accuracy and precision alignment.

- Quality control compliance.

- Waste reduction and lower rework frequency.

- Improved safety.

To summarize, gauges may seem unremarkable but accomplish so much more than that. Their impact is undeniable. Next time you catch a glimpse of someone using a gauge, remember it is more than just a tool; it is an integral part of attaining accuracy.

FAQs

A gauge is an instrument for measuring the size of an object. It is useful in verifying if the items meet a given requirement.

Types of gauges include plug gauges, ring gauges, snap gauges, taper gauges, thread gauges, and feeler gauges.

Plug gauges are cylindrical tools used for checking the size of holes. A hole may be checked with a plug gauge which has a GO side and a NO-GO side.

A feeler gauge measures gaps or spaces present between two parts. It is made of thin metal strips of different thicknesses.

It’s very important to have gauges in manufacturing since they help in making sure that the parts being worked on are done on the accurate size which helps keep the quality and safety standards of the work.

Of course, gauges can get worn out through regular usage which might change their accuracy in measurement, it is advisable to check and calibrate them frequently.