Cold-rolled steel (CRS) gives a unique mix of strength, durability and flexibility that has come as an important element in modern construction. Cold-rolled steel is needed to create the built environment, from framing materials to structural elements. This blog explains the properties, applications and advantages of cold-rolled steel sections that are used in steel-framed constructions.

What is Cold-Rolled Steel?

‘Cold-formed steel’ or CFS are a steel product that is created at room temperature using methods like bending and pressing. Because this steel is strong and flexible it is used to make these construction-related goods. CFS is strong and lightweight and commonly used in construction as a material for framing and structural elements. Cold-rolled steel belongs to the broader family of carbon steel, which forms the backbone of modern construction materials due to its excellent strength-to-weight ratio.

Hot-rolled steel is treated at high temperature and cold-rolled steel is rolled at room temperature. The cold rolling method helps improve the mechanical properties of steel and gives it a strong finish, better dimensional tolerance and a smooth surface. Cold-rolled steel that is used to make products of various sizes and shapes for different structures of buildings is made from cold-rolled coils.

How is Cold-Rolled Steel Manufactured?

Cold-rolled steel is made from coils of hot-rolled steel that are cooled at room temperature. After that, these coils have a cold rolling method which needs running them through rollers at room temperature to thicken and smooth out their surfaces. In addition to improving the surface finish of the steel, this treatment also makes it stronger and harder. The strength, hardness and surface quality of the steel are all improved by this process. Hot-rolled steel is first prepared by pickling it to remove scale and then cold-rolling is done to reduce thickness, electrolytic cleaning, annealing it to reduce internal stresses and then skin pass rolling it to improve its mechanical properties and surface finish.

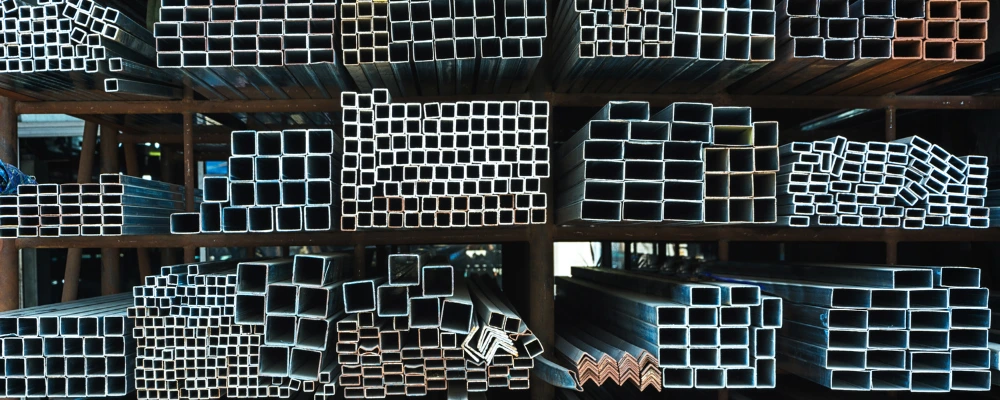

Cold-rolled steel comes in a wide range of sizes and shapes like coils, sheets and strips. These are used to make cold-formed steel components that are important for construction projects like beams, angles and channels.

Applications of Cold-Rolled Steel in Construction

There are many uses for cold-rolled steel in the construction sectors where accuracy, strength and longevity are important. Some of the applications are:

1. Framing Materials

Cold-rolled steel is used as framing material in residential, commercial and industrial buildings. It is perfect for wall studs, floor joints and roof trusses because of its great strength and low weight. Sections of cold-formed steel are also used in modular construction where accuracy and efficiency are important.

2. Steel-framed construction

For secondary structural elements like studs, joists and trusses in light-frame buildings, cold-formed steel can be used in steel-framed construction. Because of its great strength and load-bearing capacity hot-rolled steel is used for the basic structural framework in the large-scale construction projects. Cold-formed steel structures are becoming more common in high-rise and large-span construction because of their strength and flexibility. For projects requiring exceptional load-bearing capacity, builders often consider high tensile steel alternatives that offer superior strength characteristics for heavy-duty applications.

3. Cold-formed steel sections

Steel sheets are bent into the needed shapes at room temperature to create cold-formed steel sections like C-sections, Z-sections and hat sections. When lightweight and right dimensions are needed these sections are used in construction for applications like partition walls, roofing and cladding. However, because of the risk of buckling under heavy loads its use in primary load-bearing structures is not allowed.

4. Prefabricated structures

For prefabricated structures, cold-rolled steel is a great option due to its accuracy and consistency. Because these buildings are made off-site and placed together on-site construction time and labour costs are reduced. Sections of cold-formed steel are very well suited for prefabrication as they are lightweight and simple to install.

Advantages of Cold-Rolled Steel in Construction

1. High strength and durability

During the rolling process, cold-rolled steel undergoes work hardening, which increases its yield strength and makes it ideal for applications requiring precise dimensions and a smooth surface finish. In contrast, hot-rolled steel is typically used in heavy-duty structural components exposed to harsh weather conditions, thanks to its superior ductility and toughness. Cold-rolled steel is especially well-suited for cold-formed steel structures, where both strength and hardness are critical.

2. Precision and consistency

High-quality steel products are made by the cold rolling method that gives suitable dimensional tolerances and an even thickness. This choice is very important in steel-framed buildings because even small changes could damage the structural integrity of the buildings.

3. Lightweight and versatile

Sections of cold-formed steel are easy to handle and transport on building sites because they are sturdy and lightweight. Their flexibility helps engineers and architects to create detailed and creative structures without sacrificing strength and safety.

4. Sustainability

One of the materials that can be recycled the most worldwide is steel. Cold-rolled steel buildings support eco-friendly construction practices because they are recyclable and reusable. Also, prefabrication reduces on-site waste and reduces environmental effects.

When choosing between steel options for construction projects, it’s essential to understand the differences between carbon steel vs stainless steel to make informed decisions based on environmental conditions and budget considerations.

CFS vs. Hot-Rolled Steel

This comparison becomes particularly important when selecting from various types of steel used in construction, as each type serves specific structural purposes and environmental requirements.

| Features | Cold-rolled steel | Hot-rolled steel |

| Production method | Rolled at room temperature | Rolled at high temperature |

| Surface finish | Smooth, polished surface | Rough, scaled surface |

| Dimensional accuracy | High | Moderate |

| Strength | Higher yield strength due to work hardening | Lower, unless heat-treated |

| Applications | Lightweight framing, precision components | Heavy-duty structural components |

Challenges of Using Cold-Rolled Steel

The use of cold-rolled steel has some benefits but there are drawbacks:

- Higher initial cost: Because cold-rolled steel needs more processing than hot-rolled steel its product are generally more costly.

- Limited thickness: Cold rolling is usually applied to thinner sheets and coils. For thicker components, hot rolling is more practical.

By offering materials with exact dimensions and smooth surfaces, cold-rolled steel has helped develop buildings. It is good for some uses, like interior framing and architectural elements. Architects, engineers and builders often select cold-formed steel sections for everything from prefabricated structures to lightweight framing. As the demand for efficient and sustainable building methods grows cold-rolled steel will be used in more structures in the future. You can choose the best building materials for your project, whether it is a high-rise or a residential home, you just need to know the properties and uses of cold-rolled steel.