Nowadays, a growing number of people are turning their attention to resilient construction, especially in earthquake-prone regions. With increasing awareness of natural hazards, homeowners and builders are exploring advanced techniques to enhance the safety of buildings. Among these techniques, base isolation has emerged as a groundbreaking solution. This system works by decoupling the structure from its foundation, allowing it to move independently during seismic activity and thereby minimizing damage from ground motion.

In this Brick & Bolt blog, you will learn about base isolation, its types, benefits, and design principles.

What is Base Isolation?

Base isolation is an advanced earthquake-resistant technique designed to reduce the impact of seismic forces on structures. Here, flexible bearings or isolators will be included between a building’s foundation and superstructure. It decouples the structure from earth movement, considerably reducing the transmission of seismic forces. This system dissipates energy and enhances the buildings’ overall performance during earthquakes, acting as a part of resilient building design. For older structures, seismic retrofitting techniques can provide similar protective benefits.

How Base Isolation Can Protect Buildings?

During the occurrence of an earthquake, seismic waves travel through the ground and reach the building’s foundation. Rather than allowing these forces to transfer directly into the superstructure, seismic base isolators directly absorb and scatter a significant portion of the energy. The material in the base isolator, such as high-damping rubber or lead cores within the isolators, transforms kinetic energy into heat, lessening the intensity of vibrations that reach the building. This process is known as vibration damping and is important for saving both structural and non-structural elements.

Step-by-Step Breakdown

- Earthquake waves strike the building’s foundation.

- Isolators—placed between the foundation and superstructure—absorb and dissipate seismic energy, acting as a buffer.

- The superstructure moves more slowly and with less acceleration, reducing the risk of structural and non-structural damage.

The isolators work similarly to a car suspension, which allows a car to travel over rough ground without the occupants of the car getting thrown around.

Types of Base Isolation Systems

The following are the major types of base isolation systems:

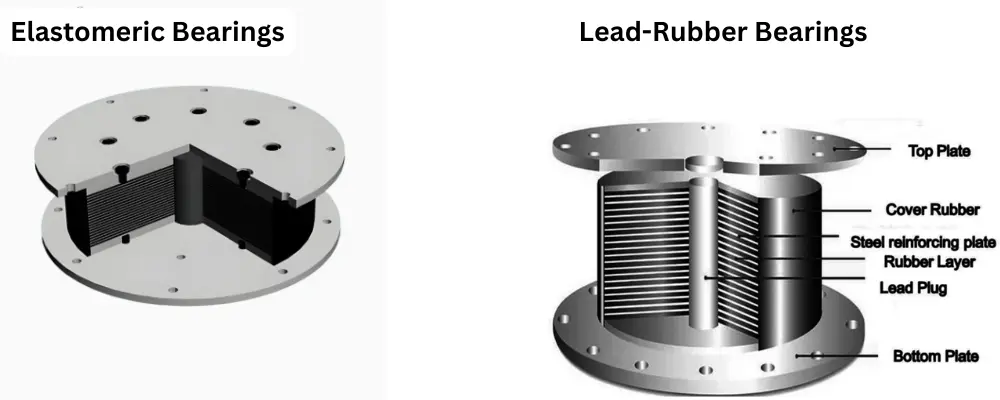

Elastomeric Bearings

These bearings are made of natural or high-damping rubber layers, often reinforced with steel shims. Natural rubber bearings give superb elasticity and vertical load capacity, while high-damping rubber variants improve energy dissipation during seismic events. At the same time, they are flexible in the horizontal direction, which allows them to move from side to side, reducing earthquake forces on structures. The steel shims inside the bearing increase vertical stiffness and help control the rubber’s sideways expansion (bulging). This supports the bearing’s stability and prevents too much sideways movement.

When designing elastomeric bearings, engineers focus on three main factors:

- The bearing can safely support the maximum vertical load.

- Horizontal stiffness, or resistance to side-to-side movement.

- Maximum horizontal displacement is the largest side movement the bearing can allow without failing.

Pros:

- High durability and fatigue resistance

- Effective horizontal flexibility and vertical stiffness

- Simple construction and maintenance

Cons:

- Limited inherent damping in natural rubber types

- Performance can vary with temperature and ageing

Lead-Rubber Bearings

The elastomeric lead-rubber bearings are similar to plain elastomeric bearings except for a central cylinder at the core. This central cylinder is a source of larger damping because of the shear deformation of the lead material, as the plain bearings have confined energy dissipation capacity.

Lead-rubber bearings combine laminated rubber layers with a central lead core. The rubber provides flexibility, while the lead core yields under stress, dissipating energy and increasing damping.

Pros:

- High energy dissipation and damping

- Proven effectiveness in major earthquakes

- Good re-centring capability after seismic events

Cons:

- The lead core may deform permanently after extreme events

- Heavier and more expensive than simple elastomeric bearings

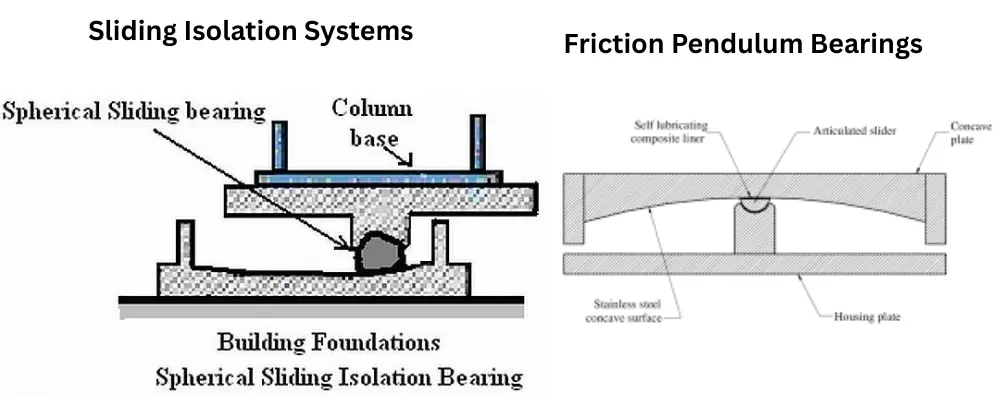

Sliding Isolation Systems

Sliding isolators are friction-based isolators that limit the transfer of shear force across the isolation interface. They use sliding elements between the foundation and the superstructure. Based on the shape of the interface between the sliding elements, they are classified into flat slider bearings and curved slider bearings. They do this using sliding parts placed between the foundation and the building (superstructure). Depending on the shape of the surface where the sliding happens, sliding isolators are divided into two types:

- Flat slider bearings—these have a flat sliding surface.

- Curved slider bearings—these have a curved sliding surface.

The movement of the sliding parts is controlled by systems like:

- High-tension springs

- Laminated rubber bearings

- Or the curved shape of the sliding surface itself

These systems help bring the structure back to its original position (called the equilibrium position) after the shaking stops. This return motion is known as the restoring force.

Pros:

- Low friction enables large displacements.

- Minimal maintenance is required.

- Suitable for retrofitting existing structures.

Cons:

- Limited restoring force may require additional recentering devices.

- Potential for wear and debris accumulation on sliding surfaces.

Friction Pendulum Bearings

This is a type of seismic isolator that will be used in buildings to lessen the impacts of strong earthquakes. They act as a pendulum to support the building to move more slowly and smoothly during shaking.

An FPS has three main parts:

- A curved (concave) stainless steel surface

- A Teflon-like material that helps reduce friction

- A slider that sits between the building and the base

When an earthquake happens, the slider moves along the curved surface, which slightly lifts the building. This movement:

- Slows down the shaking (by increasing the building’s natural period)

- Reduces the force going into the structure

- Dissipates energy through friction between the slider and the curved surface

The curved shape of the bearing helps the building come back to its original position after the earthquake, just like a pendulum swinging back.

Pros:

- Consistent period of vibration regardless of displacement

- High energy dissipation through friction

- Self-centering capability

Cons:

- More complex design and installation

- Sensitivity to surface wear and contamination

Benefits of Base Isolation in Building Construction

- Significant Reduction in Seismic Forces: Base isolation in buildings is one of the safest methods for seismic upgrading by significantly reducing seismic forces applied to the structure.

- Foundation-Level Intervention: All strengthening work is done at the foundation level, minimising disturbance to residents.

- Limited Non-Structural Damage and Business Interruption: Reduces extra costs that you need to spend on interior damage and operational downtime.

- Localised Damage: In major seismic events, damage is concentrated at the isolators, making repairs easy and avoiding building evacuation.

- Minimal Vibrations and Accelerations: Upper parts of the building experience limited movement, protecting valuable content.

- Suitable for High-Value Buildings: Ideal for buildings with high financial, architectural, or cultural value (e.g., industries, historical buildings, museums).

Challenges & Limitations of Base Isolation Systems

- High Cost for Smaller Projects: This earthquake-resistant building technique is still an expensive solution, especially for buildings up to 10 floors.

- Applicability Limitations: Cannot be applied to buildings in contact with others on any side (e.g., buildings in city centres).

- Limited Structural Compatibility: It offers limited compatibility to the structure. Still requires freedom of movement around the perimeter, which many existing buildings do not have.

- Need for Specialised Expertise: Demands advanced knowledge in both design and construction, limiting its widespread adoption.

- Limited Real-World Application: Currently used mainly for high-profile or large-scale projects, reinforcing the misconception that it’s only suitable for prominent structures.

Real-life Example in India

In India, this base isolation technique was first introduced for Gujarat’s Bhuj Hospital in 2003, after the aftermath of the famous Bhuj earthquake. This earthquake-proofing technique has now been widely adopted in many earthquake-prone regions of India.

Although the initial cost of including a base isolation system in a building is high and requires periodic maintenance, it has proven to be a reliable earthquake safety measure time and again. Brick & Bolt’s innovative approach to earthquake-proof building techniques highlights their commitment to resilient building design. Their expertise in delivering quality homes makes them an ideal partner for implementing these advanced technologies as the building industry continues to evolve.