Steel is a commonly used metal that has various applications in diverse industries, ranging from AEC (Architecture, Engineering and Construction) to aerospace and kitchenware. With advancements in technology and innovation, many different types of steel have been developed, of which carbon steel is one of the most widely used. Keep reading to learn all about what carbon steel is, how it is manufactured, the properties of the material, its types and uses in the construction industry.

What is Carbon Steel?

Carbon steel is a metal alloy mainly composed of iron and having a carbon content between 0.05% and 1.3% by weight. According to the American Iron and Steel Institute (AISI), the carbon steel chemical composition does not have any specified amounts for other alloying materials like nickel, cobalt, molybdenum, chromium, tungsten, vanadium and titanium. However, the Copper content must be between 0.4%- 0.6%, Manganese < 1.65% and Silicon < 0.6%. Due to the many benefits that it offers, such as low cost and high strength, this material has many wide-ranging applications in the construction industry.

How is Carbon Steel Manufactured?

Iron ores are extracted from natural deposits and then combined with coke (a special coal) and limestone. Next, these ingredients are heated in a blast furnace at 1200- 1400 ºC. During heating, the coke’s carbon dissolves into the molten iron, increasing its carbon content. This produces pig iron, which is rich in carbon. The remaining impurities then form slag with the limestone and rise to the surface for removal. Afterwards, the carbon amount is reduced to the desired level through further refining. Finally, the material undergoes casting, rolling, and/ or heat treatment to produce carbon steel in the required shapes, forms and size.

Properties of Carbon Steel

Some of the main carbon steel material properties are as follows:

| Property | Definition | Specifications | |

Physical Properties | Carbon Steel Density | It indicates how much mass is packed into a given volume of the material. | 7.7-7.9 g/cm3 |

Mechanical Properties | Hardness | Measures the material’s surface resistance to wear and scratches. | 125-580 Brinell |

| Yield Strength | Measures the stress point at which material flexibility ends and permanent bending begins. | 250-800 MPa | |

| Ultimate Tensile Strength | Maximum load a material can handle before completely failing. | 450-1600 MPa | |

| Modulus of Elasticity | It shows how stiff and firm the material is, depicting its ability to prevent deformation under stress. It influences the structural integrity of carbon steel. | 190-210 GPa | |

| Poisson’s Ratio | It refers to how much a material deforms in one direction when it is stressed in another direction. | 0.28-0.30 | |

| Shear Modulus | Measures the shear stiffness or resistance to deformation under shear stress. | 72-80 GPa | |

| Thermal Properties | Thermal Expansion | It describes how materials respond to various temperature conditions. | 11-16.6 µm/m.K |

Carbon Steel Melting Point | It refers to the temperature at which a material changes from solid to liquid, which is helpful for welding and joining processes. | 1450-1700 ºC | |

| Thermal Conductivity | Ability of a material to conduct heat. | 24.5-65.2 W/m-K | |

| Specific Heat | Energy needed to raise the temperature of 1 unit mass by 1 degree. | 0.470-0.519 J/g-ºC | |

| Electrical Properties | Electrical Resistivity | It measures the material’s opposition to the flow of electric current through itself. | 0.213 µΩ/m(at 70º C) |

Types of Carbon Steel

Based on the carbon content in steel, the material can be classified into four types. According to the Indian Standards codes IS 7226 (1974) and IS 513 (2008), the compositions of these types of steel are as follows:

| Type | Steel Designation | Carbon | Manganese | Silicon | Sulphur (Max) | Phosphorous (Max) | Titanium | Chromium | Tungsten |

| Low Carbon | CR1 | 0.15 | 0.6 | – | 0.035 | 0.05 | – | – | – |

| CR2 | 0.12 | 0.5 | – | 0.035 | 0.04 | – | – | – | |

| CR3 | 0.1 | 0.45 | – | 0.03 | 0.025 | – | – | – | |

| CR4 | 0.08 | 0.4 | – | 0.03 | 0.02 | – | – | – | |

| CR5 | 0.06 | 0.25 | – | 0.02 | 0.02 | 0.15 | – | – | |

| Medium Carbon | C40 | 0.35 – 0.45 | 0.6 – 0.9 | 0.15 – 0.35 | 0.04 | 0.04 | – | – | – |

| C55 | 0.5 – 0.6 | 0.5 – 0.65 | 0.15 – 0.35 | 0.04 | 0.04 | – | – | – | |

| High Carbon | C70 | 0.65 – 0.75 | 0.5 – 0.8 | 0.1 – 0.35 | 0.04 | 0.04 | – | – | – |

| C80 | 0.75 – 0.85 | 0.5 – 0.8 | 0.1 – 0.35 | 0.04 | 0.04 | – | – | – | |

| C85 | 0.8 – 0.9 | 0.5 – 0.8 | 0.1 – 0.35 | 0.04 | 0.04 | – | – | – | |

| C98 | 0.9 – 1.05 | 0.5 – 0.8 | 0.1 – 0.35 | 0.04 | 0.04 | – | – | – | |

| High Carbon Low Alloy | 120Cr35 | 1.1 – 1.3 | 0.3 – 0.6 | 0.25 max | 0.03 | 0.03 | – | 0.2 – 0.5 | – |

| 110Cr35W2 | 1 – 1.2 | 0.3 – 0.6 | 0.35 max | 0.03 | 0.03 | – | 0.2 – 0.5 | 2 – 2.5 |

Low Carbon Steel

Low carbon steel, also called mild steel (MS), has a Carbon content of less than 0.25%. It is the least expensive type of steel, but also has lower strength. Its properties include a significantly low melting point, making it easy to weld or mould into different shapes. Commonly used types are sheet and strip steel, tubing and piping steel, pressure vessel steel and galvanized steel.

Medium Carbon Steel

Medium carbon steel has a carbon content between 0.3% and 0.6%. It is relatively stronger and more resistant to wear. It can offer a balance between ductility and hardness. These properties make it ideal for producing bars (square, rectangular and round), sheets and wires for use in construction.

High Carbon Steel

High carbon steel material has a carbon content between 0.6% and 1.05%. Important properties include a high tensile strength and hardness, but low ductility and higher brittleness make it vulnerable to cracks under stress. Commonly used types are plain high-carbon steel, tool steel, bearing steel and spring steel.

Advantages

- It has high tensile strength and durability.

- It can be heat-treated, is easily weldable, and can be moulded into the desired shapes.

- It is more budget-friendly when compared to other steel types.

- It can be easily produced and is accessible worldwide.

- It is resistant to heavy vibrations and stresses.

Disadvantages

- It rusts easily, especially in regions with warm and humid climates or high salt content in the air.

- Very high temperatures, such as those experienced in regions with a hot and dry climate, can weaken and warp the material.

- The higher the carbon content in carbon steel, the more likely it is to crack under stress.

- Regular maintenance, coatings, and painting are required to protect and preserve the material.

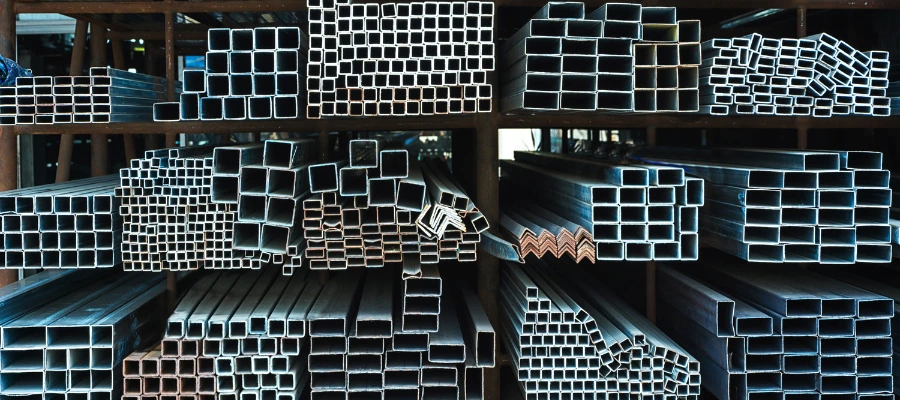

Uses of Carbon Steel in Construction

Depending on the material composition, this steel type can be used for various structural and non-structural applications in buildings. These include making components like:

- Load-bearing elements like beams, columns, braces, anchors, foundations and slabs in frame-type construction.

- Reinforcement for concrete elements like slabs, beams, columns and foundations.

- Roofing and cladding systems with sheets, plates and bars.

- Lightweight staircase components like treads, risers, railings, balustrades and landings.

- Building components like doors and windows.

- Supporting elements like anchor bolts, base plates and rivets for joining together or strengthening different building elements.

- Pipes and container vessels.

- Construction tools such as drills, saws, hammers, chisels and wrenches.

- Carbon steel plates and sheets are used to make HVAC ductwork.

Using the Best Steel in Your Project

Carbon steel is a reliable material with many uses. Its strength and affordability make it a popular choice across diverse industries. While it has some limitations, selecting the right grade ensures optimal performance. Brick & Bolt, an end-to-end construction services provider in India, offers the best building materials supply to streamline building processes. A patented quality assessment system (QASCON) with 470+ tests also ensures that projects are completed with premium quality. To use top-quality construction materials like steel in your project, connect with Brick & Bolt today!