Concrete, specifically concrete slabs, are one of the most commonly used elements in modern home construction. Forming an essential part of building structures, concrete slabs come in various types offering customisable shapes, sizes, spans and loading options. Read on to learn more about some of the most commonly used types in contemporary slab construction.

A slab is a horizontal element of a building structure, generally made of RCC (Reinforced Cement Concrete) and forms the roofs and floors of buildings, while providing a flat surface for building usage. It helps in transferring different types of load such as live and dead loads to the columns, beams, foundation and other supporting members to ensure stability of a structure.

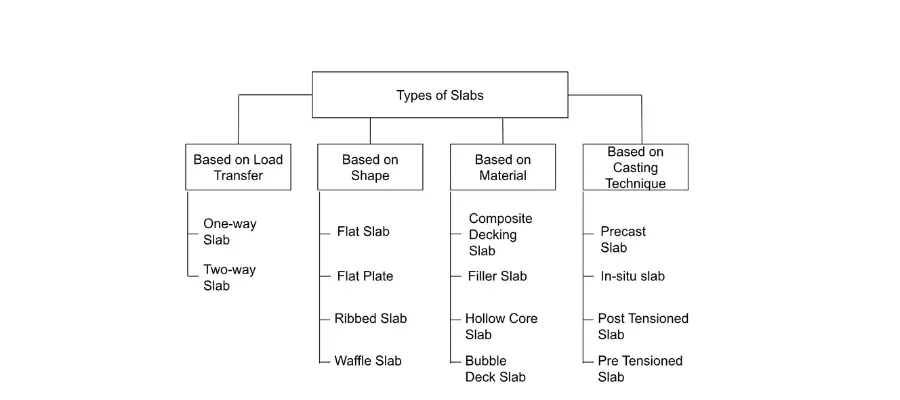

Types of Concrete Slabs

Different types of concrete slabs can be designed based on specific site and project requirements. Typically built types of slabs can be categorised as follows:

- Types of Slabs Based on Load Transfer

RCC slabs generally transfer load in only one or two directions, which gives the major classification based on load transfer.

- One-way Slabs

A one-way slab transfers load along only one direction, onto parallelly placed supporting elements such as beams, columns or load-bearing walls. These supports are generally on the two shorter sides of the slab. However, a slab that is supported on four sides can also be called one-way if the ratio of its length to its width (L/B) is more than two. These slabs experience bending only in one direction, which is the direction perpendicular to its supporting sides. Major steel reinforcement bars to counteract tension are also placed along this direction, with minimal bars in the other direction.

- Two-way Slabs

When an RCC slab is supported on all four sides by beams, columns or load bearing walls, it is called a two-way slab. A two-way slab is more squarish in shape, meaning that the ratio of its length to its width (L/B) is less than two. The load in such a slab is transferred along both directions and the slab also experiences bending in these two directions. Main steel reinforcement bars are provided equally along both directions to resist bending moments, leading to a higher amount of steel required as compared to one-way slabs.

- Types of Slabs Based on Shape

- Flat Plate

A flat plate slab is directly supported on columns or load bearing walls, without any beams. Easier and faster formwork, leading to speedy construction, is a major advantage of flat plate slabs. This type of slab is generally used in public buildings like hotels, multi-storey offices or residences and hospitals, due to the clean and uninterrupted ceiling surfaces that they provide, which can be utilised for running other services like HVAC and fire extinguishing pipes. However, flat plate slabs can generally be used for maximum spans of 12m.

- Flat Slab

Flat slabs are a type of slabs that have evolved from flat plates, due to requirements of higher spans accompanied with clean ceiling aesthetics. They also do not have any beam supports, but instead rest on drop panels, column heads or a combination of both, which form the tops of columns. These form slab thickenings at the joint between columns and the slab, reducing the overall depth of the slab required. They can bear higher loads compared to flat plate slabs, and the absence of beams makes them an ideal choice for public buildings with large floor spans.

- Ribbed Slab

A ribbed slab is a type of one-way slab, with small beam-like projections at the bottom of the slab, known as ribs or joists. Multiple ribs run parallel to the shorter direction of the slab, providing additional support to it. It helps in reducing the overall depth of the slab and main beams by incorporating steel only in tension points along the ribs. The ribs form rectangular pockets along the ceiling surface, which can be utilised for creating false ceilings or to create horizontal directionality in a space.

- Waffle Slab

Waffle slabs consist of equally spaced ribs along both directions, forming a waffle-like appearance at the bottom of ceilings. These are a type of two-way slabs that help in floor insulation as hot air gets trapped in the waffle pockets. They can be utilised to create floors with very large spans and heavy loads and provide structural stability while minimising material usage. Waffle slabs are most commonly used as slabs that form roofs for parking areas. However, such slabs require extensive formwork, are more expensive, time-consuming and labour intensive.

- Types of Concrete Slabs Based on Material

- Composite Decking Slab

A composite slab consists of materials that are typically not part of RCC slabs, such as steel decking sheets and steel beams. The need for formwork in this type of slab is eliminated as the steel decking itself acts as formwork for concrete to be poured, thus reducing construction time. Steel decking sheets are normally profiled, to ensure additional load capacities with lighter slab weights. Decking is usually trapezoidal or re-entrant in shape, and its depth can vary between 80 mm and 300 mm.

- Filler Slab

A filler slab utilises objects such as clay pots and tiles, to reduce the amount of steel and concrete in a slab. Steel bars are provided in the tension zones and eliminated in compression areas to be replaced with these objects. The behaviour of these slabs is very similar to conventional RCC slabs. Filler slabs promote the use of greener materials and ensure thermal comfort, since the filler materials are usually made of clay which creates cool temperatures. They also create an aesthetically unique ceiling look. However, reduced cost of materials may be negated by the increased cost of labour.

- Hollow Core Slab

With equally spaced continuous voids in circular or oval shapes, hollow core slabs are generally precast and prestressed. These slabs are almost twice as strong as conventional slabs, due to the prestressing of steel bars and allow large spans of up to 20m without intermediate supports. They are also lightweight and more sustainable, owing to the use of reduced amounts of cement and steel. However, hollow core slabs are generally thicker (thickness ranges from 125mm to 500mm), which may lead to increased floor-to-floor heights. Increased resistance to steel corrosion is ensured with increased thicknesses.

- Bubble Deck Slab

Bubble deck slabs are similar to filler slabs, but have plastic balls or bubbles placed between the concrete instead of clay tiles or pots. These plastic balls are made of high density polypropylene materials and are not visible at the bottom of the roof. This kind of a slab is generally precast and reduces the weight of the structure by reducing concrete requirement in the slab. Such slabs however have increased depths, ranging between 230mm to 600mm. Reduced amounts of steel and cement usage, combined with reduced transportation costs due to their light weights, make these slabs economical.

- Types of Slabs based on Casting Technique

- Precast Slabs

Precast slabs are slabs whose concrete has been poured and hardened in factory setups away from the actual construction site. Mass manufacturing in factories ensures uniform quality, strength and finishing. They are generally produced in standard sizes with simple on-site installation joints that ensure efficient and speedy construction, which is especially beneficial in the construction of multi-story buildings with repetitive floor slab layouts. Such slabs also generally offer the added advantage of recyclability at the end of the building’s life cycle, due to their easy dismantling process. Decreased labour costs may however be negated by increased transportation and manufacturing costs.

- Slabs Cast In-situ

As the name suggests, In-situ slabs or site-cast slabs entail mixing and pouring of the concrete for slabs on actual construction sites. This is the most common type of slabs, in particular for low-rise buildings and independent homes. Offering increased design freedom and customisability, these are more cost-effective for small projects. The necessary concrete admixtures can be included and appropriate curing conditions can be ensured as per specific site and design requirements. However, proper supervision is necessary to ensure good quality, adequate curing and strength gain. Unfavourable weather conditions may negatively affect the concrete mixing and pouring processes.

- Post Tensioned Slabs

Tensioning is a process in which steel reinforcement bars (tendons) are stretched and tightened to create tension. When this process is done after the concrete has hardened to an extent, it results in the creation of post tensioned slabs. Tendons are placed in ducts left between concrete and stretched. This process strengthens and hardens concrete, while also giving it an enhanced ability to resist cracks since the slab has already undergone expansion. Such slabs have increased load bearing capacities and provide stability in challenging soil conditions such as swamps and marshes. A significant drawback of this technique is the noticeable increase in cost.

- Pre Tensioned Slabs

These are very similar to post tensioned slabs, with the major difference being that steel reinforcement bars are tensioned prior to pouring and hardening of concrete. Steel tendons are anchored between supports on two ends or in a frame and stretched to their tolerance limits by machines. Concrete is then poured around it and the tendons are released after it gains sufficient strength. Although offering increased compressive strength, this technique is also cost intensive.

Slab design

The selection of the ideal type of slab for home design requires careful considerations and calculations of dead and live loads, slab spans and loading capacity. Structural or civil engineers are necessary to provide recommendations and slab designs that are site and project specific. Drawings provided by them include technical details such as slab depth and span, reinforcement sizing and spacing and formwork details, which need to be precisely followed by contractors on site to ensure structural stability during and after slab construction. Contact Brick & Bolt for a one-stop solution to design and construct your dream home, with slabs that fulfill both functional and aesthetic requirements.